Wholesale Low Melt Bags For Wire And Cable Manufacture - Batch Inclusion Bags – Zonpak

Wholesale Low Melt Bags For Wire And Cable Manufacture - Batch Inclusion Bags – Zonpak Detail:

Batch inclusion bags are designed for packaging compounding ingredients in rubber or plastic mixing process to improve the batch uniformity. Bags with different melting points are suitable for different mixing conditions. Due to their low melting point and good compatibility with rubber, the bags together with the chemicals or additives inside can be direct put into an internal mixer. The bags can easily melt and fully disperse into the compounds as a minor ingredient.

Using batch inclusion bags can help rubber plants improve batch uniformity, provide cleaner work environment, save expensive additives, and increase work efficiency. Bags of different melting points, sizes, thickness, and colors are available to meet the customers’ requirements.

|

Technical Standards |

|

| Melting point available | 72, 85, 105 deg. C |

| Physical properties | |

| Tensile strength | ≥12MPa |

| Elongation at break | ≥300% |

| Appearance | |

| There is no bubble, hole and poor plasticization. Hot sealing line is flat and smooth without weak seal. | |

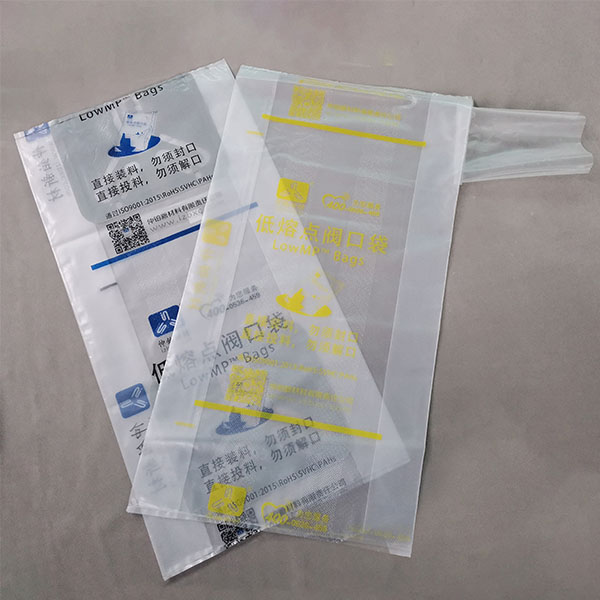

Product detail pictures:

Related Product Guide:

We've been convinced that with joint efforts, the enterprise between us will bring us mutual benefits. We could guarantee you item excellent and aggressive price tag for Wholesale Low Melt Bags For Wire And Cable Manufacture - Batch Inclusion Bags – Zonpak, The product will supply to all over the world, such as: Norwegian , Zurich , Hamburg , By integrating manufacturing with foreign trade sectors, we can provide total customer solutions by guaranteeing the delivery of right products to the right place at the right time, which is supported by our abundant experiences, powerful production capability, consistent quality, diversified product portfolios and the control of the industry trend as well as our mature before and after sales services. We'd like to share our ideas with you and welcome your comments and questions.

This company conforms to the market requirement and joins in the market competition by its high quality product, this is an enterprise that have Chinese spirit.