Wholesale Dealers of Printed Flexible Packaging Film – EVA Batch Inclusion Film – Zonpak

Wholesale Dealers of Printed Flexible Packaging Film – EVA Batch Inclusion Film – Zonpak Detail:

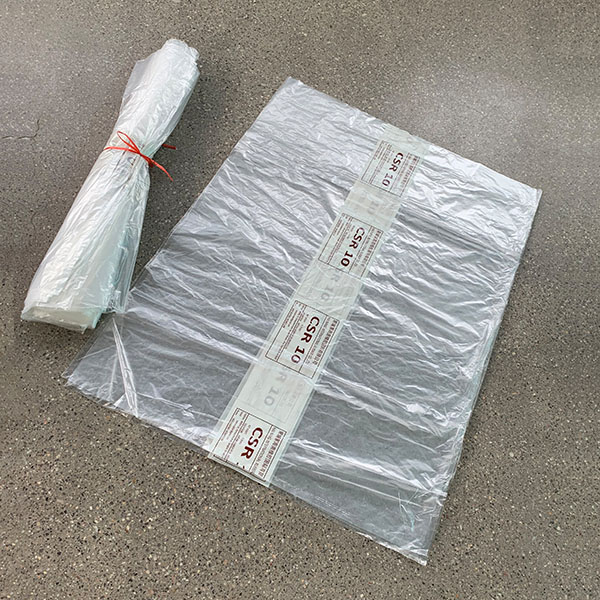

ZonpakTM EVA batch inclusion film is a special kind of packaging film with specific low melting point. It is mainly used on the automatic FFS (form-fill-seal) packing machine to make little packages (100g-5000g) of rubber additives or chemicals. Due to the film’s property of low melting point and good compatibility with rubber and plastic, these little packages can be direct put into an internal mixer during mixing process, and the bags will melt and fully disperse into the mix as an effective ingredient. It brings convenience to the material users and eliminates packaging waste disposal.

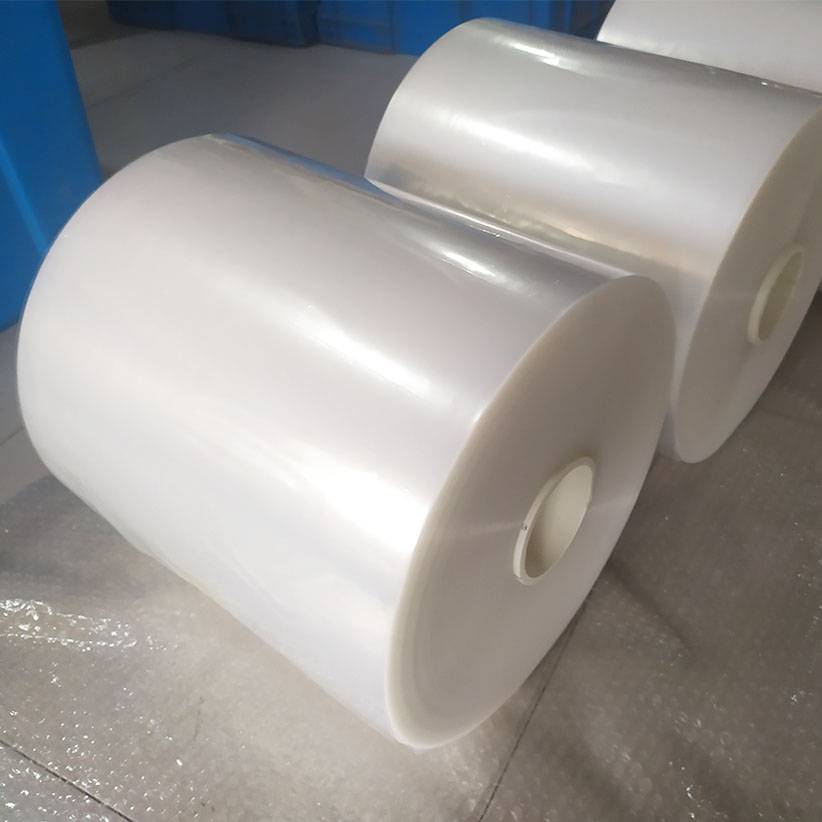

Different melting points are available as customers required. Stable chemical properties and high physical strength of the film make it suitable for most rubber chemicals and automatic packaging machines.

|

Technical Standards |

|

| Melting point | 65-110 deg. C |

| Physical properties | |

| Tensile strength | MD ≥16MPa TD ≥16MPa |

| Elongation at break | MD ≥400% TD ≥400% |

| Modulus at 100% elongation | MD ≥6MPa TD ≥3MPa |

| Appearance | |

| Surface of the product is flat and smooth, there is no wrinkle, no bubble. | |

Product detail pictures:

Related Product Guide:

To create more value for customers is our business philosophy; customer growing is our working chase for Wholesale Dealers of Printed Flexible Packaging Film – EVA Batch Inclusion Film – Zonpak, The product will supply to all over the world, such as: Finland , United Arab Emirates , Hyderabad , With the goal of "zero defect". To care for the environment, and social returns, care employee social responsibility as own duty. We welcome friends from all over the world to visit and guide us so that we can achieve the win-win goal together.

This is a reputable company, they have a high level of business management, good quality product and service, every cooperation is assured and delighted!