Renewable Design for Low Melt Batch Inclusion Bags - Low Melt Valve Bags – Zonpak

Renewable Design for Low Melt Batch Inclusion Bags - Low Melt Valve Bags – Zonpak Detail:

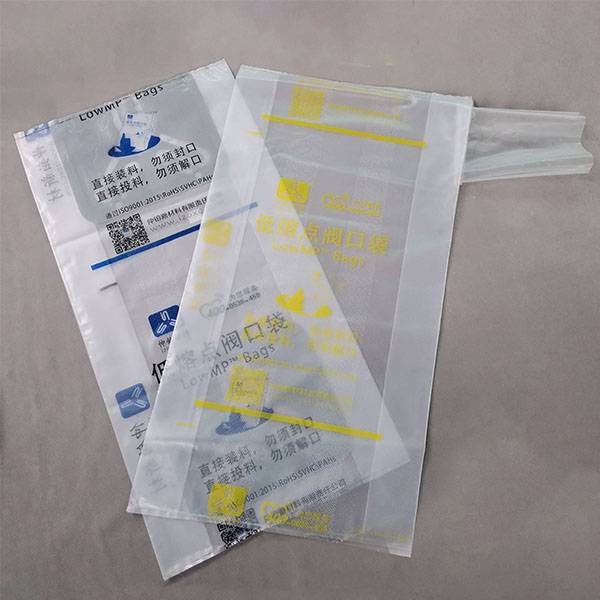

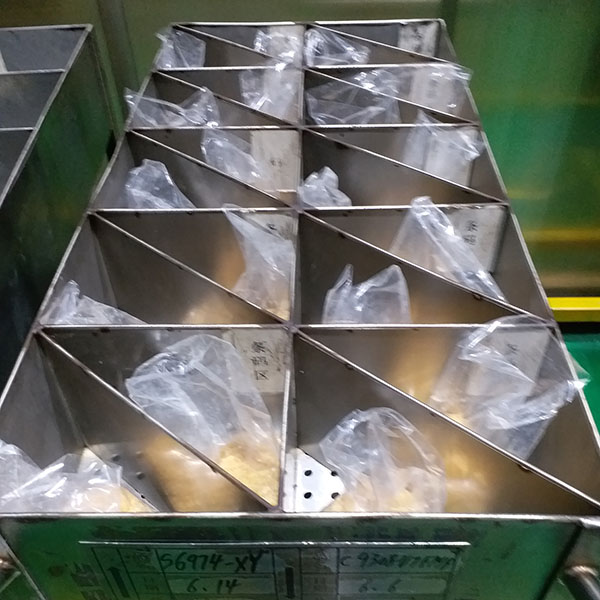

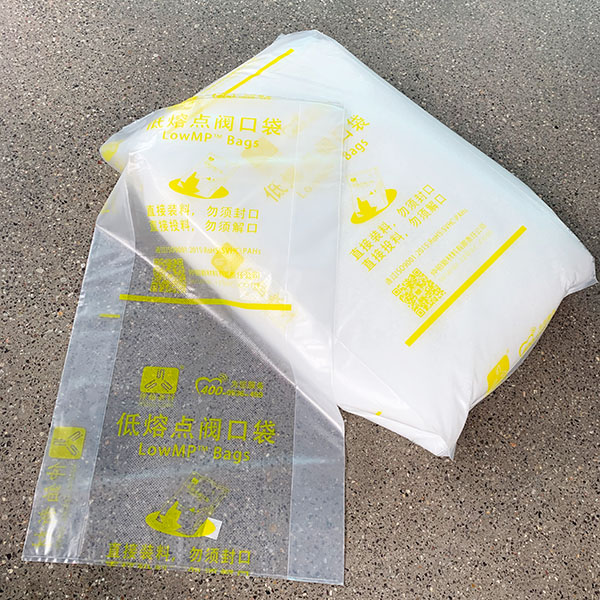

Low melt valve bags are specially designed for the industrial packaging of rubber and plastic additives. Using the low melt valve bags with an automatic filling machine, material suppliers can make standard packages e.g. 5kg, 10kg, 20kg and 25kg which can be direct put into an internal mixer by the material users. The bags will melt and fully disperse in the rubber or plastic mixture as a minor effective ingredient in the compounding and mixing process. So it is more popular than paper bags.

BENEFITS:

- No fly loss of materials

- Improved packing efficiency

- Easy stacking and palletizing

- Assure accurate adding of materials

- Cleaner work environment

- No packaging waste left

APPLICATIONS:

- rubber and plastic pellet or powder, carbon black, silica, zinc oxide, alumina, calcium carbonate, kaolinite clay

OPTIONS:

- Gusset or block bottom, embossing, venting, color, printing

SPECIFICATION:

- Material: EVA

- Melting point: 65-110 deg. C

- Film thickness: 100-200 micron

- Bag width: 350-1000 mm

- Bag length: 400-1500 mm

Product detail pictures:

Related Product Guide:

With our abundant experience and considerate products and services, we have been recognized to be a reputable supplier for a lot of global consumers for Renewable Design for Low Melt Batch Inclusion Bags - Low Melt Valve Bags – Zonpak, The product will supply to all over the world, such as: Congo , Kuwait , French , We are trying our best to make more customers happy and satisfied. we sincerely hope to establish a good long-term business relationship with your esteemed company thought this opportunity,based on equal, mutual beneficial and win win business from now till the future.

It can be said that this is a best producer we encountered in China in this industry, we feel lucky to work with so excellent manufacturer.