Renewable Design for Low Melt Batch Inclusion Bags - Low Melt Valve Bags for Kaolinite Clay – Zonpak

Renewable Design for Low Melt Batch Inclusion Bags - Low Melt Valve Bags for Kaolinite Clay – Zonpak Detail:

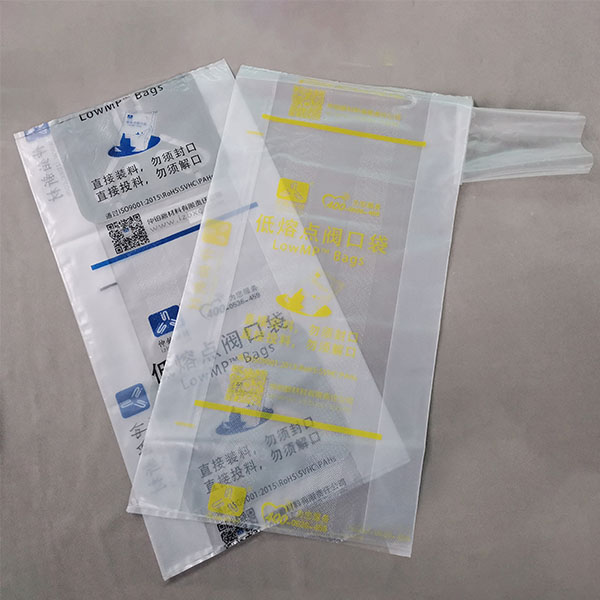

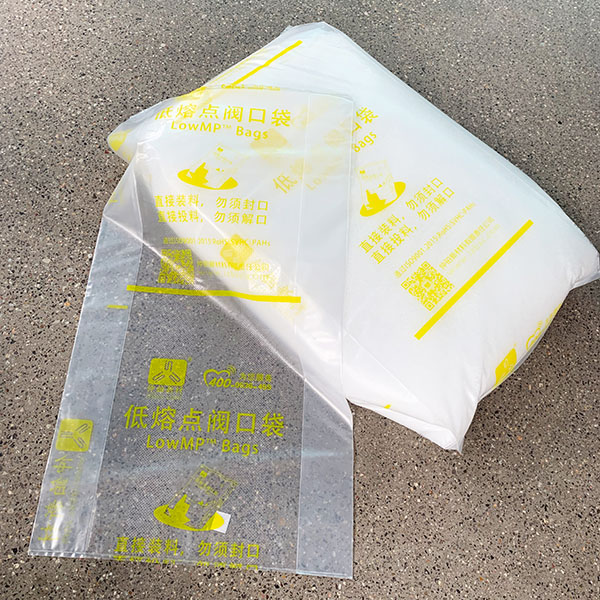

Kaolinite clay for rubber industry is usually packed in kraft paper bags, and paper bags are easy to break during transportation and difficult to dispose after used. To solve these problems, we have specially developed low melt valve bags for the material manufacturers. These bags together with the materials contained can be direct put into a banbury mixer because they can easily melt and fully disperse in the rubber compounds as an effective ingredient. Different melting points (65-110 deg. C) are available for different using conditions.

Using low melt valve bags can eliminate the fly loss of the materials when packing and there is no need for sealing, so it largely improves the packaging efficiency. With standard packages and no need for unpacking before using the materials, low melt valve bags also facilitate the work of the material users.

OPTIONS:

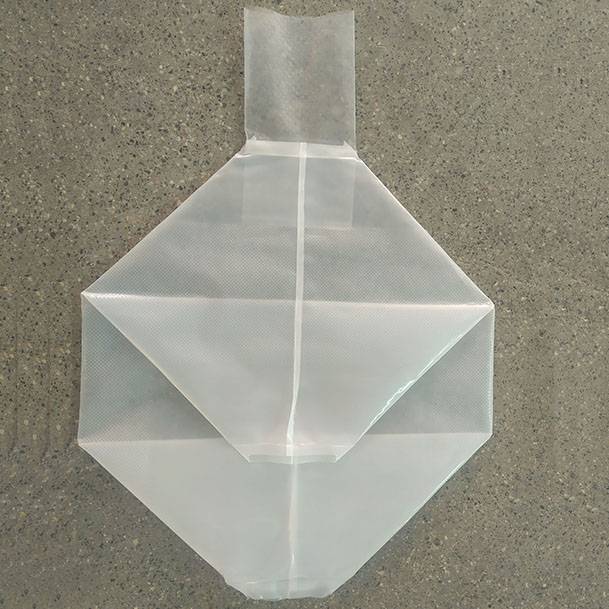

- Gusset or block bottom, embossing, venting, color, printing

SPECIFICATION:

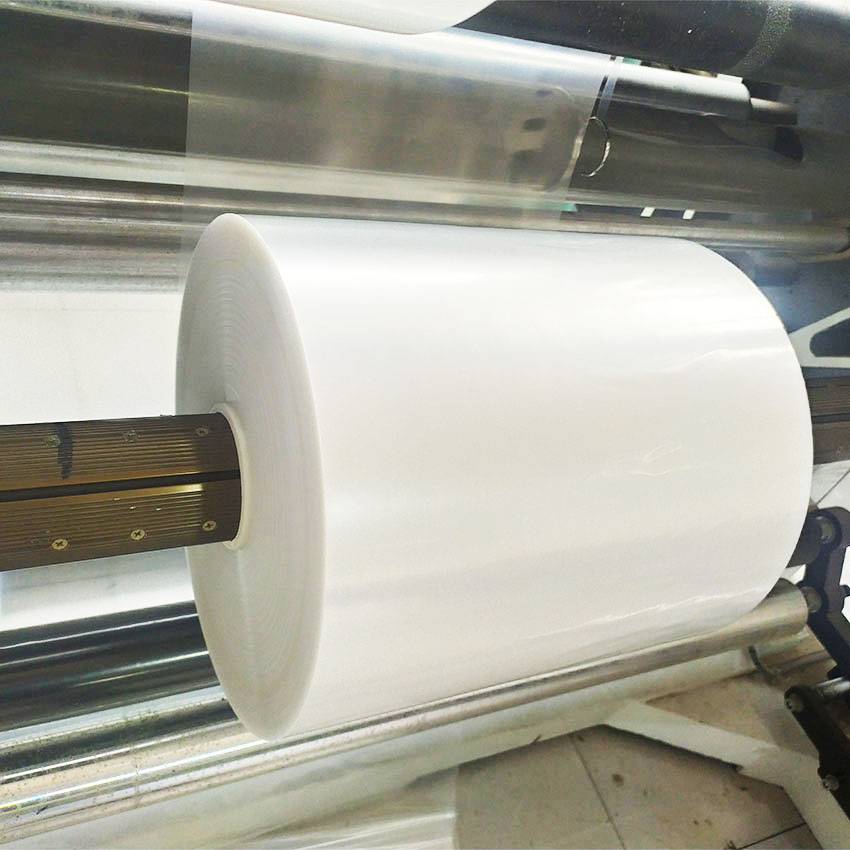

- Material: EVA

- Melting point: 65-110 deg. C

- Film thickness: 100-200 micron

- Bag size: 5kg, 10kg, 20kg, 25kg

Product detail pictures:

Related Product Guide:

Our commission is to serve our buyers and purchasers with most effective good quality and aggressive portable digital goods for Renewable Design for Low Melt Batch Inclusion Bags - Low Melt Valve Bags for Kaolinite Clay – Zonpak, The product will supply to all over the world, such as: Peru , Sri Lanka , belarus , We care about every steps of our services, from factory selection, product development & design, price negotiation, inspection, shipping to aftermarket. We have implemented a strict and complete quality control system, which ensures that each product can meet quality requirements of customers. Besides, all of our products have been strictly inspected before shipment. Your Success, Our Glory: Our aim is to help customers realize their goals. We are making great efforts to achieve this win-win situation and sincerely welcome you to join us.

The sales person is professional and responsible, warm and polite, we had a pleasant conversation and no language barriers on communication.