PriceList for Low Melt Bags For Tire Manufacture - Low Melt Batch Inclusion Bags – Zonpak

PriceList for Low Melt Bags For Tire Manufacture - Low Melt Batch Inclusion Bags – Zonpak Detail:

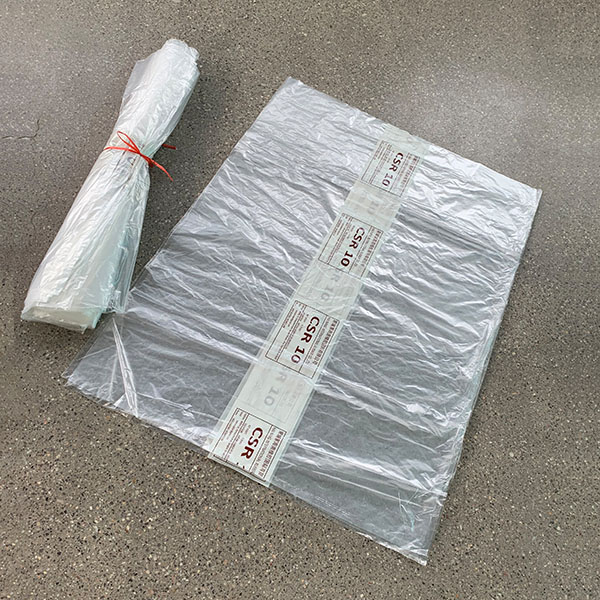

With particular low melting points and good compatibility with rubber and plastics, the EVA batch inclusion bags are specially designed for the rubber or plastic compounding process. The bags are used to pre-weigh and temporarily store the rubber ingredients and additives, and they can be direct thrown into a banbury mixer during compounding process. Using low melting batch inclusion bags can help ensure accurater adding of chemicals, keep the mixing area clean, minimizes the worker exposure to harmful materials and increases the compounding efficiency.

PROPERTIES:

1. Different melting points (from 70 to 110 deg. C) are available as required.

2. Good physical strength, such as high tensile strength, impact strength, puncture resistance, flexibility, and rubber-like elasticity.

3. Excellent chemical stability, nontoxic, good environmental stress cracking resistance, weather resistance and compatibility with most rubber e.g. NR, BR, SBR, SSBR.

APPLICATIONS:

Various rubber chemicals and additives (e.g. carbon black, silica, anti-aging agent, accelerator, curing agent and rubber process oil

Product detail pictures:

Related Product Guide:

We generally believe that one's character decides products' top quality, the details decides products' high-quality ,along with the REALISTIC,EFFICIENT AND INNOVATIVE team spirit for PriceList for Low Melt Bags For Tire Manufacture - Low Melt Batch Inclusion Bags – Zonpak, The product will supply to all over the world, such as: Iran , British , Sydney , We have more than 100 works in the plant, and we also have a 15 guys work team to service our customers for before and after sales. Good quality is the key factor for the company to stand out from other competitors. Seeing is Believing, want more information? Just trial on its products!

This enterprise in the industry is strong and competitive, advancing with the times and develop sustainable, we are very pleased to have a opportunity to cooperate!