OEM/ODM China FFS Film For Rubber Chemicals - Low Melt FFS Film – Zonpak

OEM/ODM China FFS Film For Rubber Chemicals - Low Melt FFS Film – Zonpak Detail:

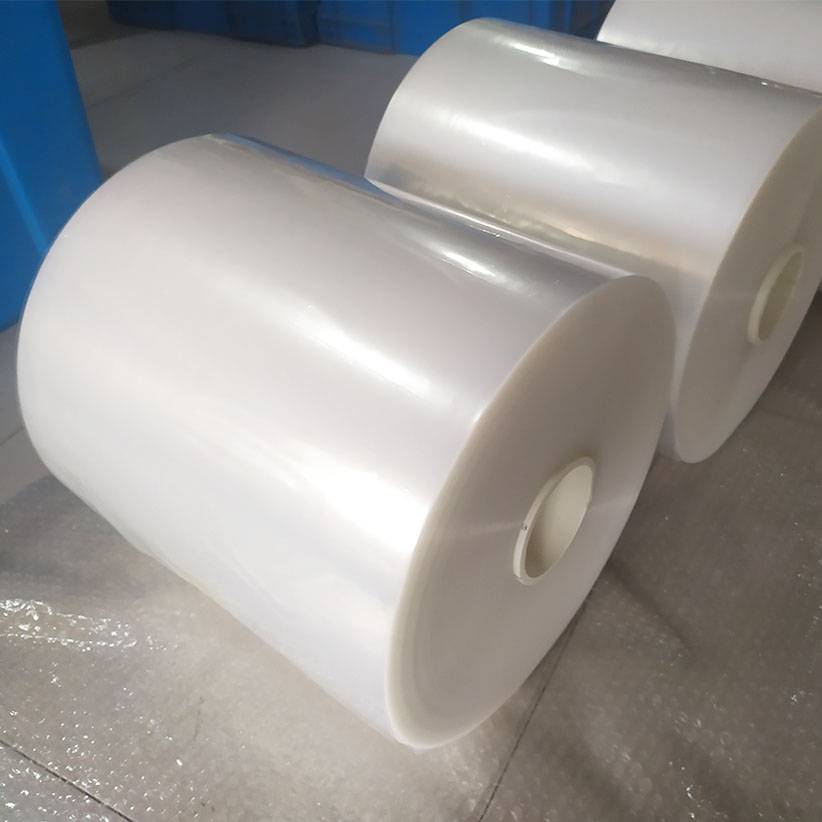

Form-Fill-Seal (FFS) bagging machines are often used to make little packages (100g-5000g) of rubber and plastic additives or chemicals to meet the compounding demand of the tire and rubber industry. ZonpakTM low melt FFS film is specially designed for the FFS bagging machine. The film is made of EVA (copolymer of ethylene and vinyl acetate) resin which has a lower melting point than PE, rubber like elasticity, no toxicity, good chemical stability and high compatibility with natural and synthetic rubbers. So the bags together with contained materials can be direct put into a mixer, and the bags can easily melt and disperse into the rubber or plastic as a minor effective ingredient.

Films with different melting points and thickness are available to meet different application requirements.

|

Technical Standards |

|

| Melting point | 65-110 deg. C |

| Physical properties | |

| Tensile strength | MD ≥16MPa TD ≥16MPa |

| Elongation at break | MD ≥400% TD ≥400% |

| Modulus at 100% elongation | MD ≥6MPa TD ≥3MPa |

| Appearance | |

| Surface of the product is flat and smooth, there is no wrinkle, no bubble. | |

Product detail pictures:

Related Product Guide:

Our organization sticks to your principle of "Quality may be the life of your organization, and reputation will be the soul of it" for OEM/ODM China FFS Film For Rubber Chemicals - Low Melt FFS Film – Zonpak, The product will supply to all over the world, such as: Uruguay , Egypt , Comoros , We've a good reputation for stable quality solutions, well received by customers at home and abroad. Our company would be guided by the idea of "Standing in Domestic Markets, Walking into International Markets". We sincerely hope that we could do business with customers both at home and abroad. We expect sincere cooperation and common development!

We have been engaged in this industry for many years, we appreciate the work attitude and production capacity of the company, this is a reputable and professional manufacturer.