OEM Manufacturer EVA Bags for rubber - Batch Inclusion Low Melt Bags – Zonpak

OEM Manufacturer EVA Bags for rubber - Batch Inclusion Low Melt Bags – Zonpak Detail:

ZonpakTM batch inclusion low melt bags are specially designed industrial packaging bags for rubber ingredients and additives used in the rubber compounding process. As the material of the bags has good compatibility with natural and synthetic rubber, these bags together with the materials contained can be direct put into a mixer, and the bags will melt and fully disperse in the rubber as a minor effective ingredient.

BENEFITS:

- Facilitate pre-weighing and handling of the materials.

- Ensure accurate dosage of ingredients, improve batch to batch uniformity.

- Reduce spill losses, prevent material waste.

- Reduce dust fly, provide cleaner work environment.

- Improve the process efficiency, reduce the comprehensive cost.

SPECIFICATION:

- Material: EVA

- Melting point: 65-110 deg. C

- Film thickness: 30-100 micron

- Bag width: 200-1200 mm

- Bag length: 250-1500mm

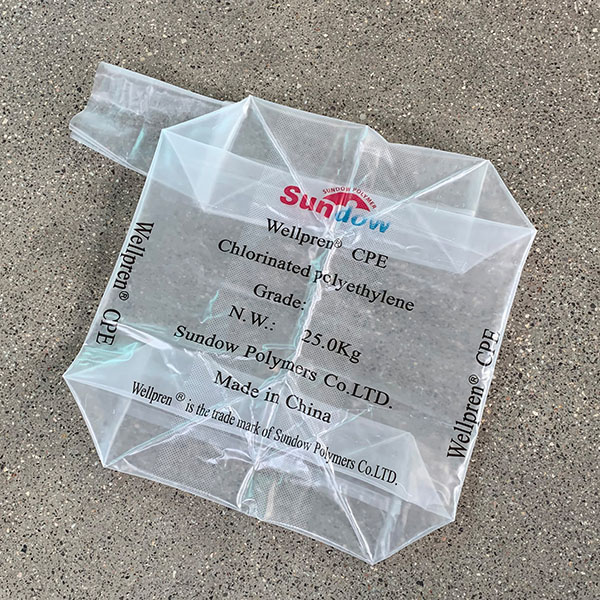

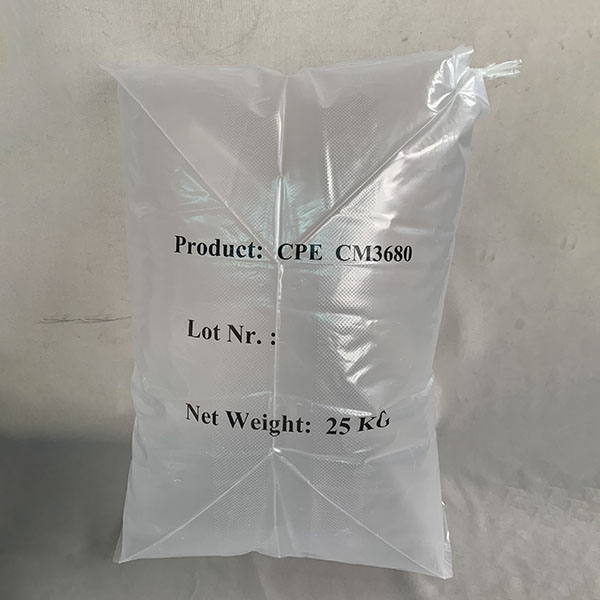

Product detail pictures:

Related Product Guide:

We support our consumers with ideal good quality merchandise and large level provider. Becoming the specialist manufacturer in this sector, we have attained wealthy practical encounter in producing and managing for OEM Manufacturer EVA Bags for rubber - Batch Inclusion Low Melt Bags – Zonpak, The product will supply to all over the world, such as: Vancouver , The Swiss , Mauritius , Our company, is always regarding quality as company' s foundation, seeking for development via high degree of credibility , abiding by iso9000 quality management standard strictly , creating top-ranking company by spirit of progress-marking honesty and optimism.

Goods just received, we are very satisfied, a very good supplier, hope to make persistent efforts to do better.