OEM manufacturer Automatic Film Packaging Machine - EVA Packaging Film for Rubber Additives – Zonpak

OEM manufacturer Automatic Film Packaging Machine - EVA Packaging Film for Rubber Additives – Zonpak Detail:

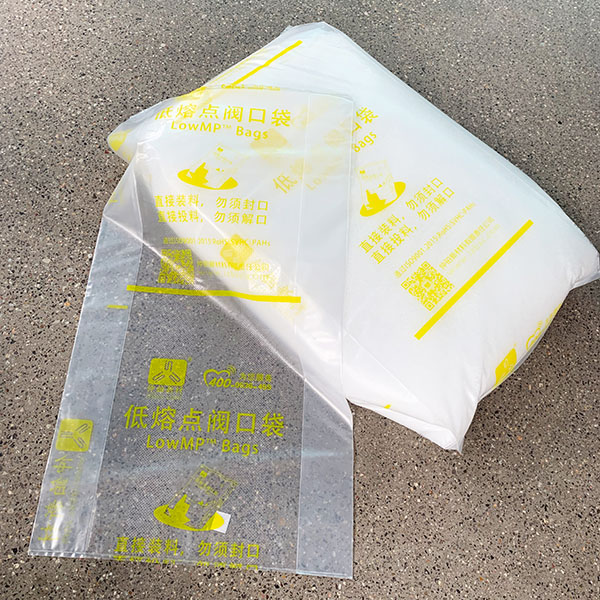

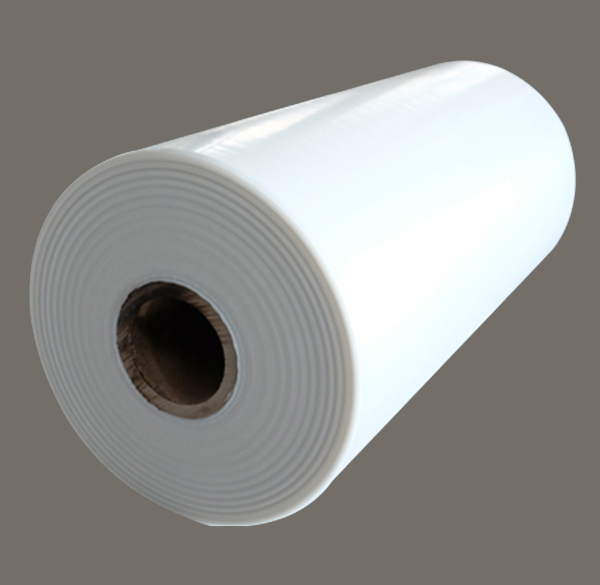

ZonpakTM EVA packaging film is specially designed to make little bags of rubber additives (e.g. 100g-5000g) with the automatic form-fill-seal (FFS) bagging machine. Various rubber additives or chemicals (e.g. rubber peptizer, anti-aging agent, curing agent, cure accelerator, rubber process oil) are commonly used in the rubber mixing process, and only little amounts of these materials are needed for each batch. So these little packages can help the material users improve work efficiency and avoid material waste. The film is made from EVA (copolymer of ethylene and vinyl acetate) which has a specific lower melting point and good compatibility with rubber or resin materials. So the bags together with the materials contained can be direct put into a mixer. The bags will melt and disperse into the rubber compound as a minor effective ingredient.

Films with different melting points (65-110 degree Celsius) and thickness are available for different using conditions.

|

Technical Standards |

|

| Melting point | 65-110 deg. C |

| Physical properties | |

| Tensile strength | MD ≥16MPa TD ≥16MPa |

| Elongation at break | MD ≥400% TD ≥400% |

| Modulus at 100% elongation | MD ≥6MPa TD ≥3MPa |

| Appearance | |

| Surface of the product is flat and smooth, there is no wrinkle, no bubble. | |

Product detail pictures:

Related Product Guide:

We have been also specializing in improving the things administration and QC system to ensure that we could preserve terrific gain within the fiercely-competitive company for OEM manufacturer Automatic Film Packaging Machine - EVA Packaging Film for Rubber Additives – Zonpak, The product will supply to all over the world, such as: Croatia , Colombia , Romania , They are sturdy modeling and promoting effectively all over the world. Never ever disappearing major functions within a quick time, it's a have to in your case of fantastic good quality. Guided by the principle of Prudence, Efficiency, Union and Innovation. the corporation. ake an excellent efforts to expand its international trade, raise its organization. rofit and raise its export scale. We've been confident that we've been going to have a bright prospect and to be distributed all over the world in the years to come.

Hope that the company could stick to the enterprise spirit of "Quality, Efficiency, Innovation and Integrity", it will be better and better in the future.