OEM China Film Packaging Material - Low Melt EVA Film – Zonpak

OEM China Film Packaging Material - Low Melt EVA Film – Zonpak Detail:

Low melt EVA film is specially designed for the packaging of rubber and plastic chemicals on FFS (form-fill-seal) automatic bagging machines. The film is featured with low melting point and good compatibility with natural and synthetic rubber. The bags made on an FFS bagging machine can be direct put into an internal mixer at the user plant because they can easily melt and fully disperse in the rubber and plastic as a minor effective ingredient.

The low melt EVA film has stable chemical properties and good physical strength, suits most rubber chemicals and automatic packaging machines.

BENEFITS:

- Reach high speed, clean and safe packing of chemical materials

- Make any size packages (from 100g to 5000g) as customer required

- Help make the mixing process easier, accurate and clean.

- Leave no packaging waste

APPLICATIONS:

- peptizer, anti-aging agent, curing agent, rubber process oil

OPTIONS:

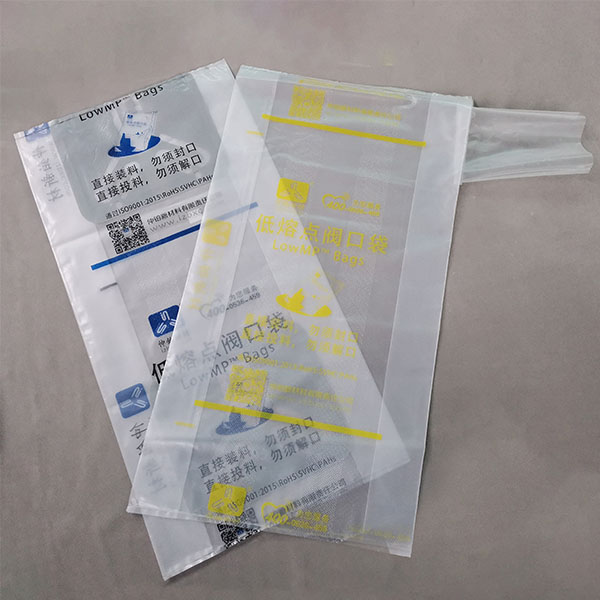

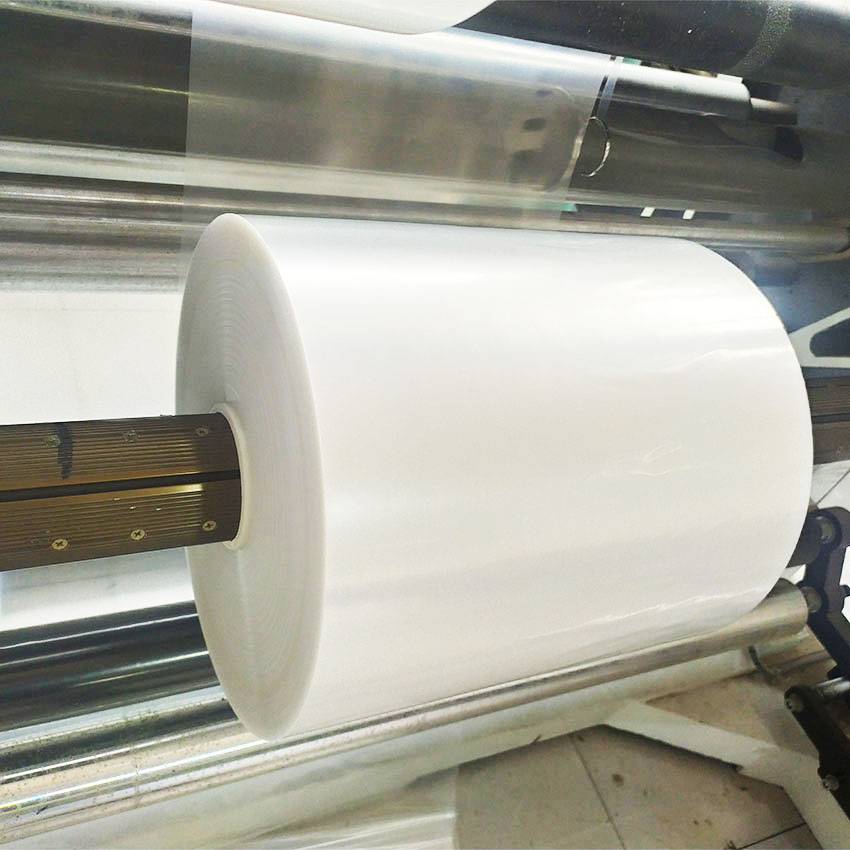

- single wound sheeting, center folded or tube form, colour, printing

SPECIFICATION:

- Material: EVA

- Melting point: 65-110 deg. C

- Film thickness: 30-200 micron

- Film width: 200-1200 mm

Product detail pictures:

Related Product Guide:

We depend on sturdy technical force and continually create sophisticated technologies to meet the demand of OEM China Film Packaging Material - Low Melt EVA Film – Zonpak, The product will supply to all over the world, such as: St. Petersburg , Netherlands , Lyon , Our Company policy is "quality first, to be better and stronger, sustainable development" . Our pursuit goals is "for society, customers, employees, partners and enterprises to seek reasonable benefit". We aspirate to do cooperate with all different the auto parts manufacturers, repair shop, auto peer , then create a beautiful future! Thank you for taking time to browse our website and we would welcome any suggestions you may have that can help us to improve our site.

High Quality, High Efficiency, Creative and Integrity, worth having long-term cooperation! Looking forward to the future cooperation!