Manufacturing Companies for Packaging Film Industry - Low Melt EVA Film – Zonpak

Manufacturing Companies for Packaging Film Industry - Low Melt EVA Film – Zonpak Detail:

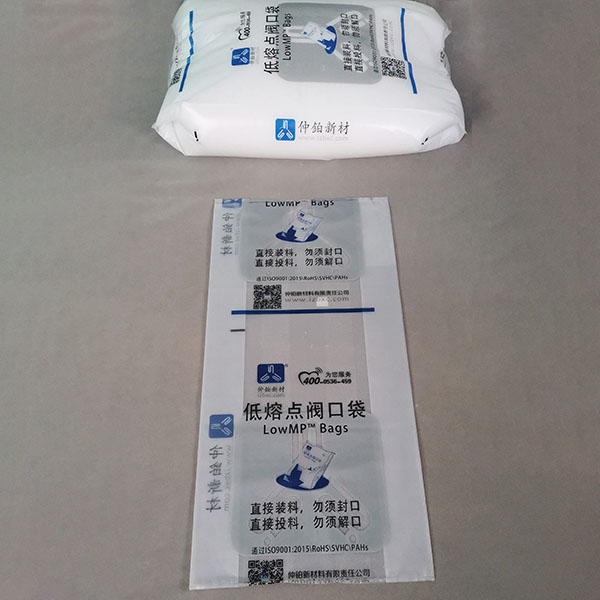

Low melt EVA film is specially designed for the packaging of rubber and plastic chemicals on FFS (form-fill-seal) automatic bagging machines. The film is featured with low melting point and good compatibility with natural and synthetic rubber. The bags made on an FFS bagging machine can be direct put into an internal mixer at the user plant because they can easily melt and fully disperse in the rubber and plastic as a minor effective ingredient.

The low melt EVA film has stable chemical properties and good physical strength, suits most rubber chemicals and automatic packaging machines.

BENEFITS:

- Reach high speed, clean and safe packing of chemical materials

- Make any size packages (from 100g to 5000g) as customer required

- Help make the mixing process easier, accurate and clean.

- Leave no packaging waste

APPLICATIONS:

- peptizer, anti-aging agent, curing agent, rubber process oil

OPTIONS:

- single wound sheeting, center folded or tube form, colour, printing

SPECIFICATION:

- Material: EVA

- Melting point: 65-110 deg. C

- Film thickness: 30-200 micron

- Film width: 200-1200 mm

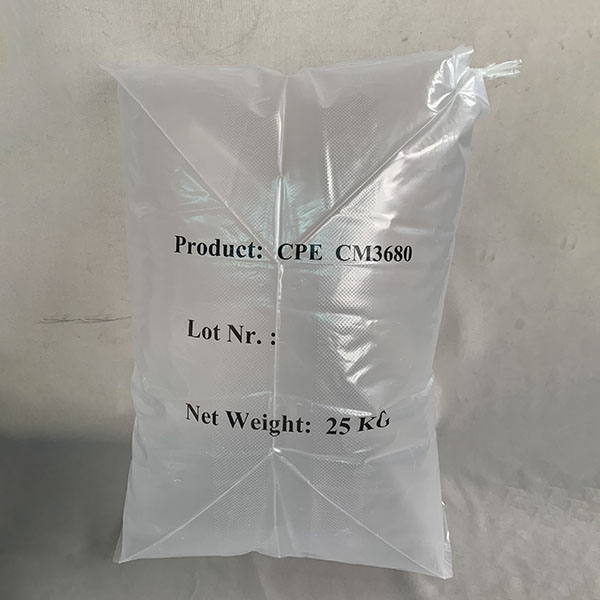

Product detail pictures:

Related Product Guide:

To create extra value for customers is our enterprise philosophy; buyer growing is our working chase for Manufacturing Companies for Packaging Film Industry - Low Melt EVA Film – Zonpak, The product will supply to all over the world, such as: Belize , America , Hongkong , Our qualified engineering team will usually be prepared to serve you for consultation and feedback. We are able to also deliver you with absolutely free samples to meet your needs. Best efforts might be made to offer you the ideal service and products. For anyone who is interested in our company and items, please make contact with us by sending us emails or contact us right away. In order to know our solutions and organization. ar more, you can come to our factory to determine it. We are going to usually welcome guests from around the globe to our corporation. o create small business relations with us. Please really feel no cost to speak to us for enterprise. nd we believe we are going to share the most effective trading practical experience with all our merchants.

The accounts manager made a detailed introduction about the product, so that we have a comprehensive understanding of the product, and ultimately we decided to cooperate.