Manufacturer of Low Melt Plastic Bags - Low Melting Bags – Zonpak

Manufacturer of Low Melt Plastic Bags - Low Melting Bags – Zonpak Detail:

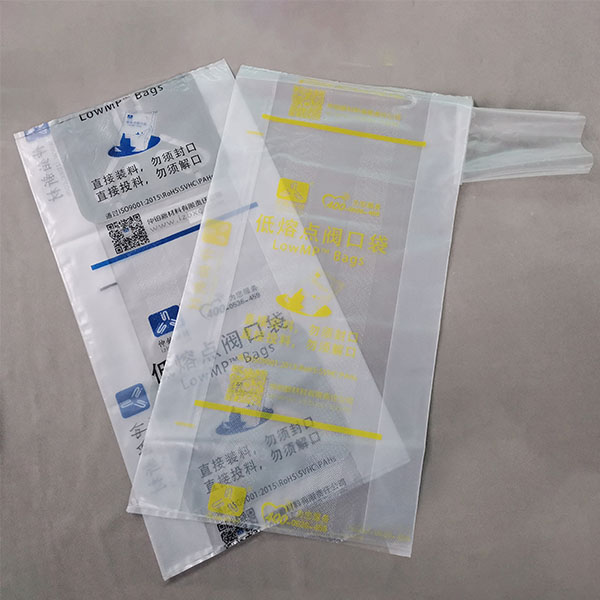

Low melting bags are also called batch inclusion bags in tire and rubber industries. These bags are made from EVA (Ethylene Vinyl Acetate) resin, and are mainly used to pack rubber ingredients (rubber chemicals and additives) in rubber compounding process. The main property of the bags are low melting point and good compatibility with rubber, so the bags together with the additives contained can be direct put into an internal mixer or mill and will fully disperse in the rubber as a minor effective ingredient.

ZonpakTM low melting bags can help provide accurate dosing of additives and clean mixing area, help get uniform rubber compounds while save additives and time.

OPTIONS:

- colour, printing

SPECIFICATION:

- Material: EVA

- Melting point: 65-110 deg. C

- Film thickness: 30-100 micron

- Bag width: 200-1200 mm

- Bag length: 250-1500mm

Product detail pictures:

Related Product Guide:

To be able to give you benefit and enlarge our business, we also have inspectors in QC Team and assure you our greatest service and products for Manufacturer of Low Melt Plastic Bags - Low Melting Bags – Zonpak, The product will supply to all over the world, such as: Qatar , Bangalore , Malta , Our company has already have pass the ISO standard and we're fully respect our customer 's patents and copyrights. If the customer provides their own designs, We will guarantee that they will likely be the only one can have that merchandise. We hoping that with our good products can bring our customers a great fortune.

The factory workers have rich industry knowledge and operational experience, we learned a lot in working with them,we are extremely grateful that we can encount a good company has excellent wokers.