Manufacturer for Low Melt EVA Plastic Bags - Low Melt Bags for Rubber Chemicals – Zonpak

Manufacturer for Low Melt EVA Plastic Bags - Low Melt Bags for Rubber Chemicals – Zonpak Detail:

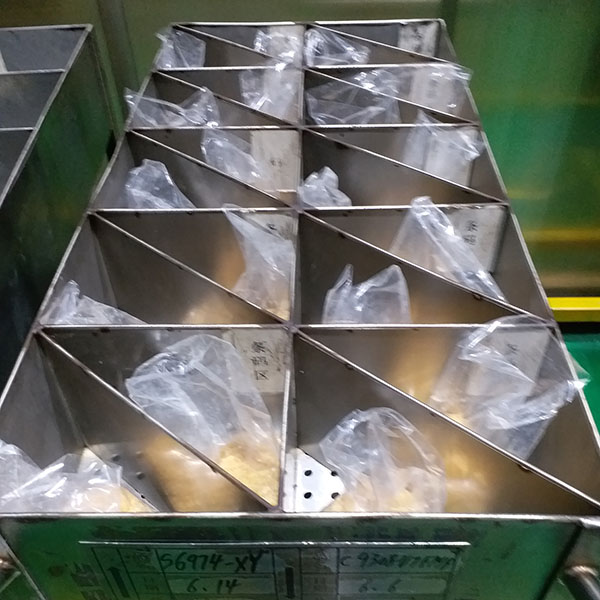

ZonpakTM Low Melt EVA Bags are specially designed industrial packaging bags for rubber chemicals and additives used in the rubber compounding process. As the material of the bags has good compatibility with natural and synthetic rubber, these bags together with the materials contained can be direct put into an internal mixer, and the bags will melt and fully disperse in the rubber as a minor ingredient.

BENEFITS:

- Make pre-weighing and handling of the chemical materials easier.

- Ensure accurate dosage of ingredients, improve batch to batch uniformity.

- Reduce spill losses, prevent waste of material.

- Reduce dust fly, provide cleaner work environment.

- Improve the process efficiency, lower the comprehensive cost.

|

Technical Datas |

|

| Melting point | 65-110 deg. C |

| Physical properties | |

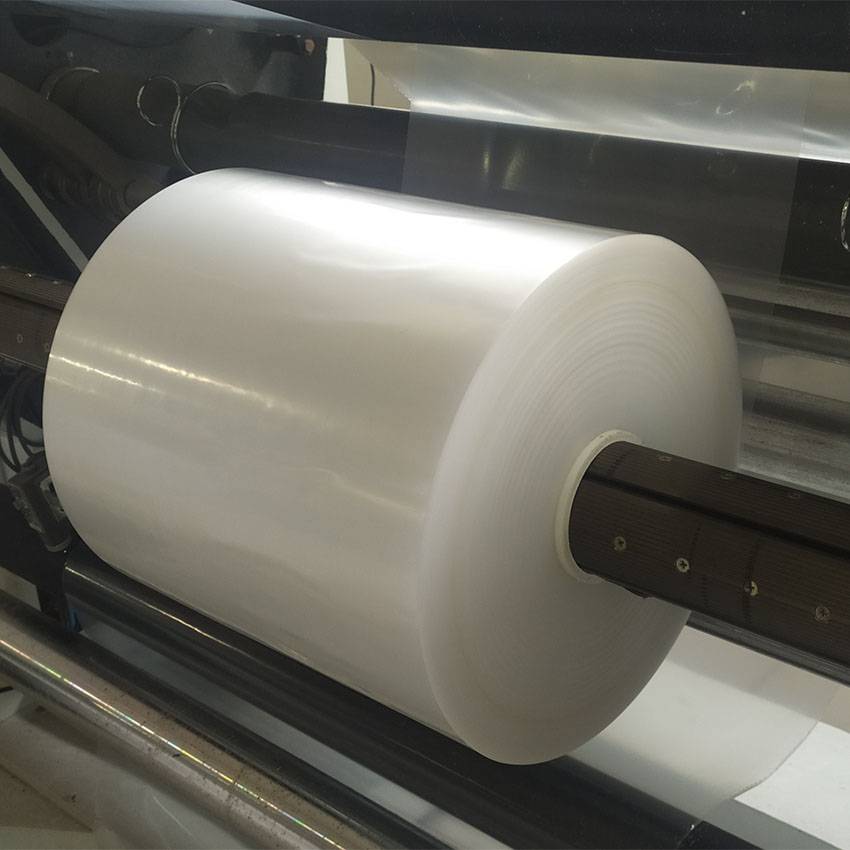

| Tensile strength | MD ≥16MPa TD ≥16MPa |

| Elongation at break | MD ≥400% TD ≥400% |

| Modulus at 100% elongation | MD ≥6MPa TD ≥3MPa |

| Appearance | |

| Surface of the product is flat and smooth, there is no wrinkle, no bubble. | |

Product detail pictures:

Related Product Guide:

The incredibly abundant projects administration experiences and 1 to one provider model make the superior importance of small business communication and our easy understanding of your expectations for Manufacturer for Low Melt EVA Plastic Bags - Low Melt Bags for Rubber Chemicals – Zonpak, The product will supply to all over the world, such as: Cologne , Belgium , Germany , Our items are widely recognized and trusted by users and can meet continuously changing economic and social needs. We welcome new and old customers from all walks of life to contact us for future business relationships and mutual success!

The factory has advanced equipment, experienced staffs and good management level, so product quality had assurance, this cooperation is very relaxed and happy!