Manufacturer for - Batch Inclusion Valve Bags – Zonpak

Manufacturer for - Batch Inclusion Valve Bags – Zonpak Detail:

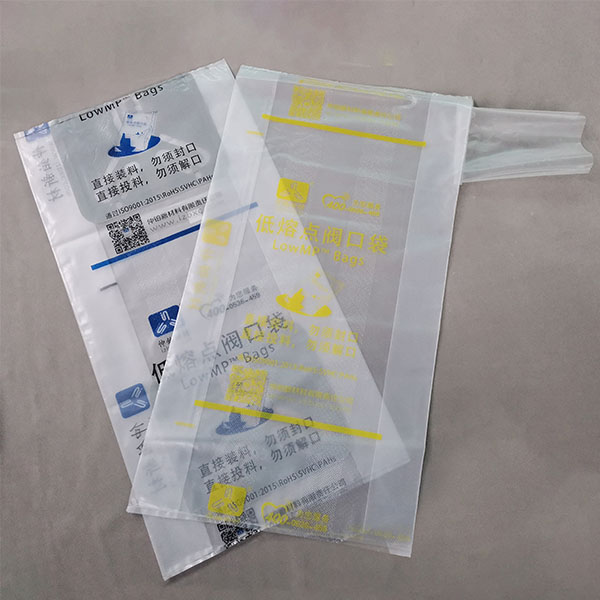

ZonpakTM batch inclusion valve bags are specially designed packaging bags for powder or pellets of rubber, plastic and rubber chemicals. With the low melt valve bags and automatic filling machines, rubber additives manufacturers can make product packages of 5kg, 10kg, 20kg and 25kg. Using the bags can eliminate the fly loss of the material when filling, and there is no need for sealing, so it can largely improve the packaging efficiency.

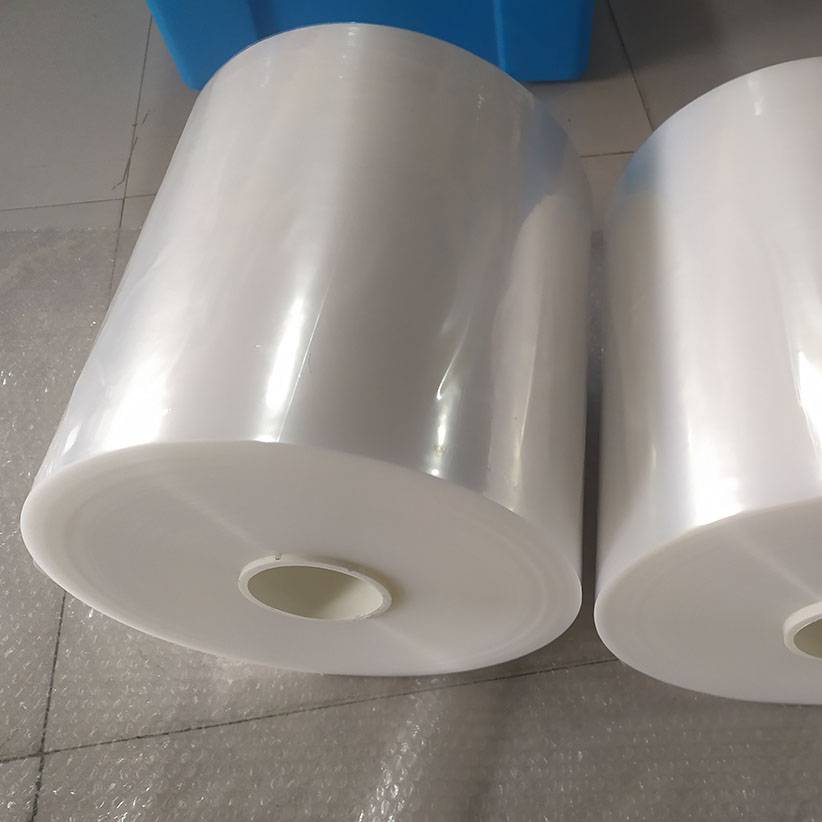

The bags are made from EVA resin and featured with specific low melting point and excellent compatibility with rubber and plastics, they can be direct put into an internal mixer, can fully disperse into the rubber or plastic as a minor ingredient. Different melting points (65-110 deg. C) are available for different application conditions. As these bags can help make the compounding work easy and clean, they are becoming more popular than paper bags to the compounders.

Side gusset and block bottom forms are available. Bag size, thickness, color, embossing, venting and printing can be customized according to customers’ specific requirement.

Product detail pictures:

Related Product Guide:

Our advantages are reduced prices,dynamic product sales workforce,specialized QC,solid factories,superior quality services for Manufacturer for - Batch Inclusion Valve Bags – Zonpak, The product will supply to all over the world, such as: Bogota , panama , Moldova , When you are keen on any of our items following you view our product list, please feel free to make contact with us for inquiries. You'll be able to send us emails and get in touch with us for consultation and we shall respond to you as soon as we are able to. If it's convenient, you could find out our address in our web site and come to our enterprise. or additional information of our items by yourself. We're generally ready to build lengthy and steady co-operation relations with any possible shoppers within the associated fields.

Wide range, good quality, reasonable prices and good service, advanced equipment, excellent talents and continuously strengthened technology forces,a nice business partner.