Low price for EVA Block Bottom Bags - Low Melt Bags for Rubber Hose Industry – Zonpak

Low price for EVA Block Bottom Bags - Low Melt Bags for Rubber Hose Industry – Zonpak Detail:

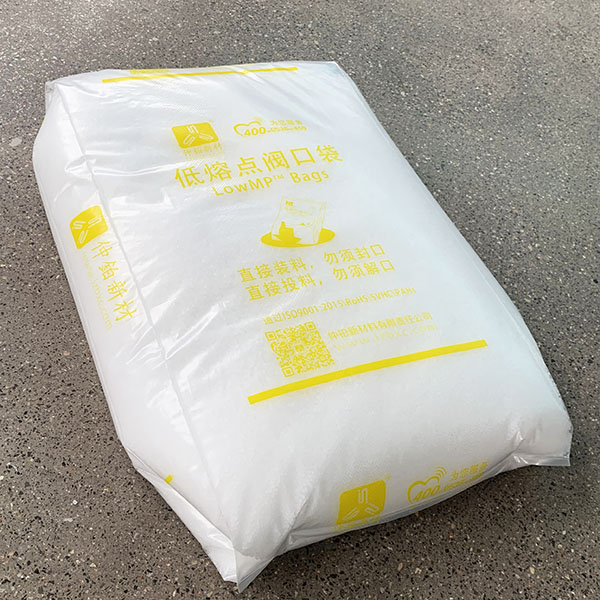

Rubber mixing plays an important role in the production of rubber hose or tube. ZonpakTM low melt EVA batch inclusion bags are designed for packaging the rubber chemicals used in the rubber compounding or mixing process. The main properties of the bags are low melting point and good compatibility with rubber, so the bags together with the additives and chemicals inside can be direct put into an internal mixer or mill. The bags can easily melt and disperse into the rubber as minor effective ingredient. Using the batch inclusion bags can help ensure accurate adding of additives, provide a cleaner work environment, save time and production cost.

Bag size and color can be customized at request.

|

Technical Standards |

|

| Melting point | 65-110 deg. C |

| Physical properties | |

| Tensile strength | MD ≥16MPa TD ≥16MPa |

| Elongation at break | MD ≥400% TD ≥400% |

| Modulus at 100% elongation | MD ≥6MPa TD ≥3MPa |

| Appearance | |

| Surface of the product is flat and smooth, there is no wrinkle, no bubble. | |

Product detail pictures:

Related Product Guide:

We take "customer-friendly, quality-oriented, integrative, innovative" as objectives. "Truth and honesty" is our administration ideal for Low price for EVA Block Bottom Bags - Low Melt Bags for Rubber Hose Industry – Zonpak, The product will supply to all over the world, such as: Madagascar , Durban , Croatia , Products have been exported to Asia, Mid-east,European and Germany market. Our company has constantly been able to update the products performance and safety to meet the markets and strive to be top A on stable quality and sincere service. If you have the honor to do business with our company. we will definitely do our very best to support your business in China.

It is really lucky to meet such a good supplier, this is our most satisfied cooperation, I think we will work again!