Hot Selling for Valve Bag Loading - Low Melt Valve Bags for CPE Pellets – Zonpak

Hot Selling for Valve Bag Loading - Low Melt Valve Bags for CPE Pellets – Zonpak Detail:

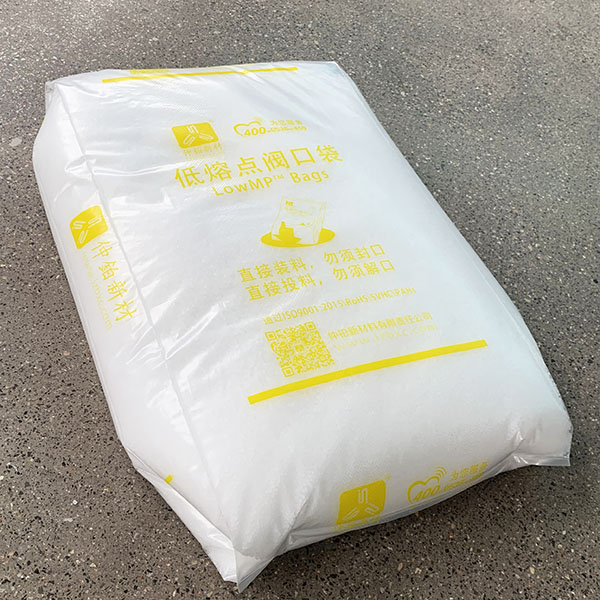

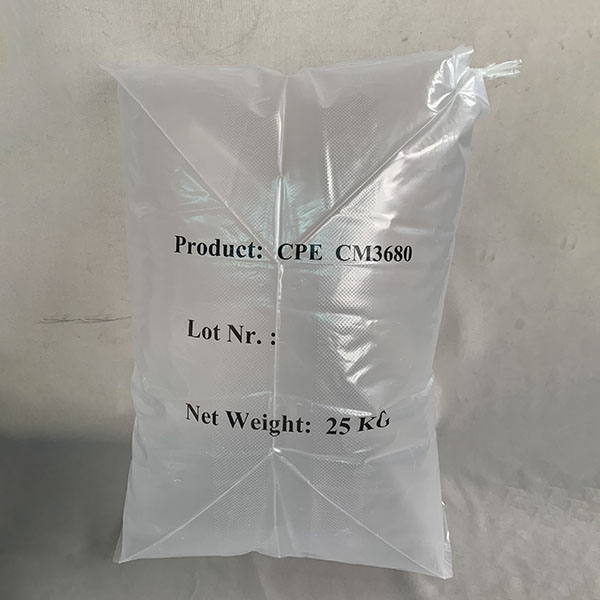

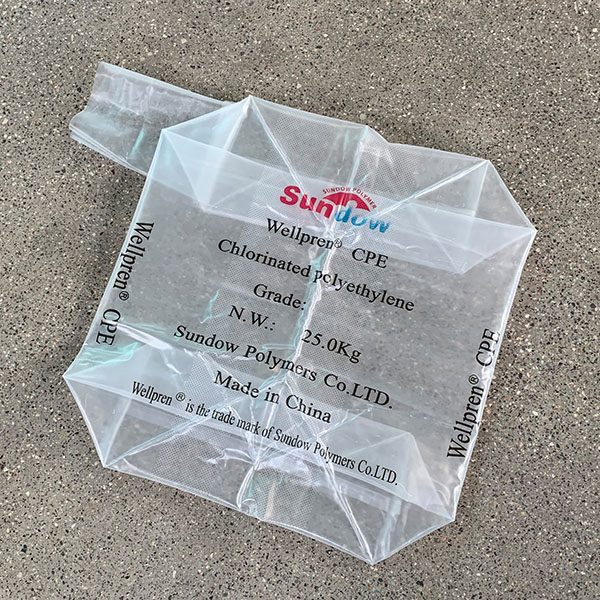

This is a specially designed packaging bag for CPE resin (Chlorinated Polyethylene) pellets. With this low melt valve bags and an automatic filling machine, CPE manufacturers can make standard packages of 10kg, 20kg and 25kg.

The low melt valve bags have a lower melting point and is highly compatible with rubber and plastic, so the bags together with the contained materials can be direct put into an internal mixer, and the bags can fully disperse into the mixture as a minor ingredient. Bags of different melting point are available for different using conditions.

OPTIONS:

- Gusset or block bottom, embossing, venting, color, printing

SPECIFICATION:

- Material: EVA

- Melting point: 65-110 deg. C

- Film thickness: 100-200 micron

- Bag width: 350-1000 mm

- Bag length: 400-1500 mm

Product detail pictures:

Related Product Guide:

Our products are greatly acknowledged and reliable by users and may fulfill repeatedly shifting financial and social wants for Hot Selling for Valve Bag Loading - Low Melt Valve Bags for CPE Pellets – Zonpak, The product will supply to all over the world, such as: Washington , Canada , Germany , With more and more Chinese products and solutions around the world, our international business is developing rapidly and economic indicators big increase year by year. We have enough confidence to supply you both better solutions and service, because we've been more and more powerful, specialist and experience in domestic and international.

We feel easy to cooperate with this company, the supplier is very responsible, thanks.There will be more in-depth cooperation.