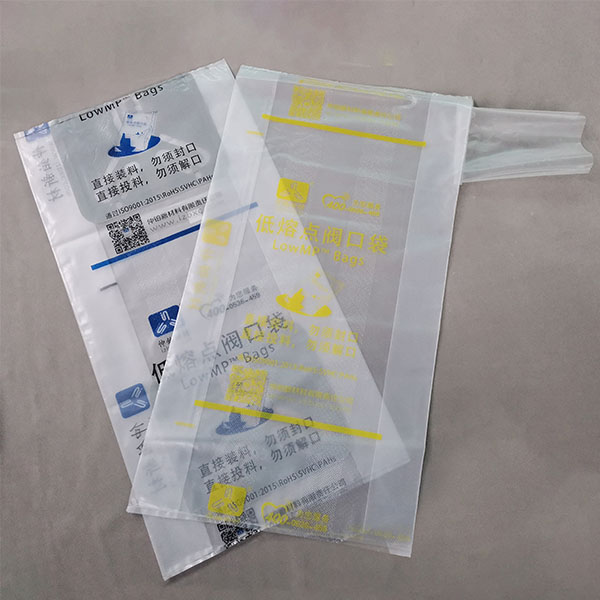

Tsawg Melt EVA Valve Hnab

ZonpakTMTsawg yaj EVA valve hnab yog tsim tshwj xeeb uas tsim cov hnab ntim rau roj hmab additives thiab resin pellets. Cov hnab no yuav tsum tau siv nrog lub tshuab filling tsis siv neeg. Ntim cov ntaub ntawv uas tsis tshua muaj EVA valve hnab, tsis tas yuav tsum tau muab khi rau tom qab ntim thiab tsis tas yuav tsum tau unsealing ua ntej muab lub hnab ntim khoom rau hauv ib lub banbury tov khoom. Yog li cov hnab EVA valve no yog qhov zoo tagnrho hloov rau cov khoom siv kraft thiab PE hnyav hnyav.

Kev kub ceev thiab kom muaj nuj nqis tuaj yeem ua tiav los ntawm qhov yooj yim tso qhov chaw nres nkoj valve rau saum lossis hauv qab ntawm lub hnab mus rau lub tshuab filling. Ntau hom valve muaj nyob rau kom phim cov tshuab filling thiab cov khoom sib txawv. Lub hnab valve yog tsim los ntawm cov ntaub ntawv tshiab, tshwj xeeb nrog qhov tsis tshua muaj melting point, zoo sib xws nrog roj hmab, khoom thiab muaj kev cuam tshuam siab. Tom qab ntim lub hnab hloov mus rau hauv lub tiaj tus cuboid, tuaj yeem ntim tau zoo. Nws yog tsim rau ntim ntawm ntau yam particle, hmoov, thiab ultra-zoo hmoov cov ntaub ntawv.

PROPERTIES:

Lub hnab nrog cov ntsiab lus sib txawv yog muaj los ua kom tau raws li cov neeg siv khoom tshwj xeeb.

Lawv muaj zoo meltability thiab dispersity nyob rau hauv cov roj hmab thiab yas.

Nrog lub zog tensile siab, cuam tshuam lub zog thiab tsis kam rau puncture, lub hnab tuaj yeem haum rau ntau lub tshuab filling.

Cov hnab ntim khoom muaj kev ruaj ntseg zoo heev, tsis muaj tshuaj lom, zoo ib puag ncig kev ntxhov siab tawg ua haujlwm, huab cua tsis kam thiab sib haum nrog cov khoom siv roj hmab xws li NR, BR, SBR, NBR.

APPLICATIONS:

Cov hnab no tsuas yog siv rau cov pob khoom ntawm 10-25kg ntawm ntau yam khoom siv los yog hmoov (xws li CPE, carbon dub, dawb carbon dub, zinc oxide, calcium carbonate) hauv kev lag luam roj hmab (tsheb, hose, daim kab xev, khau), yas ua kev lag luam (PVC, yas yeeb nkab thiab extrude) thiab roj hmab chemical kev lag luam.

| Cov Qauv Txuj Ci | |

| Melting point | 65-110 ° C. C |

| Lub cev muaj zog | |

| Tensile zog | MD ≥16MPaTD ≥16MPa |

| Elongation thaum so | MD ≥400%TD ≥400% |

| Modulus ntawm 100% elongation | MD ≥6MPaTD ≥3MPa |

| Qhov tshwm sim | |

| Qhov saum npoo ntawm cov khoom yog tiaj tus, tsis muaj wrinkle, tsis muaj npuas. | |