High reputation - Low Melt Valve Bags for Rubber Additives – Zonpak

High reputation - Low Melt Valve Bags for Rubber Additives – Zonpak Detail:

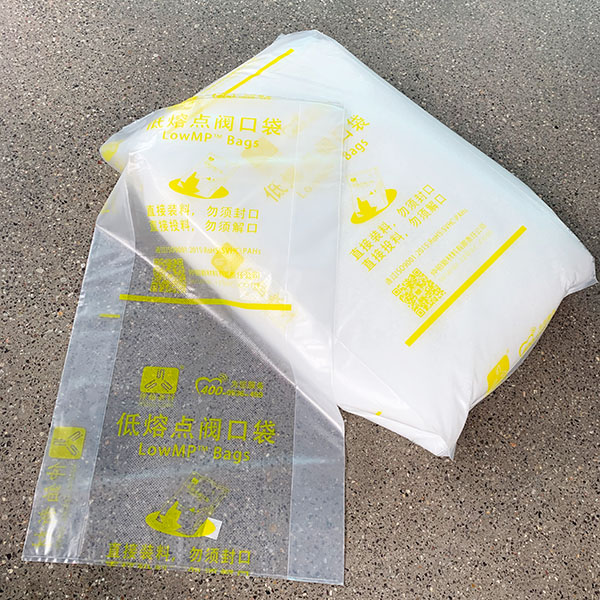

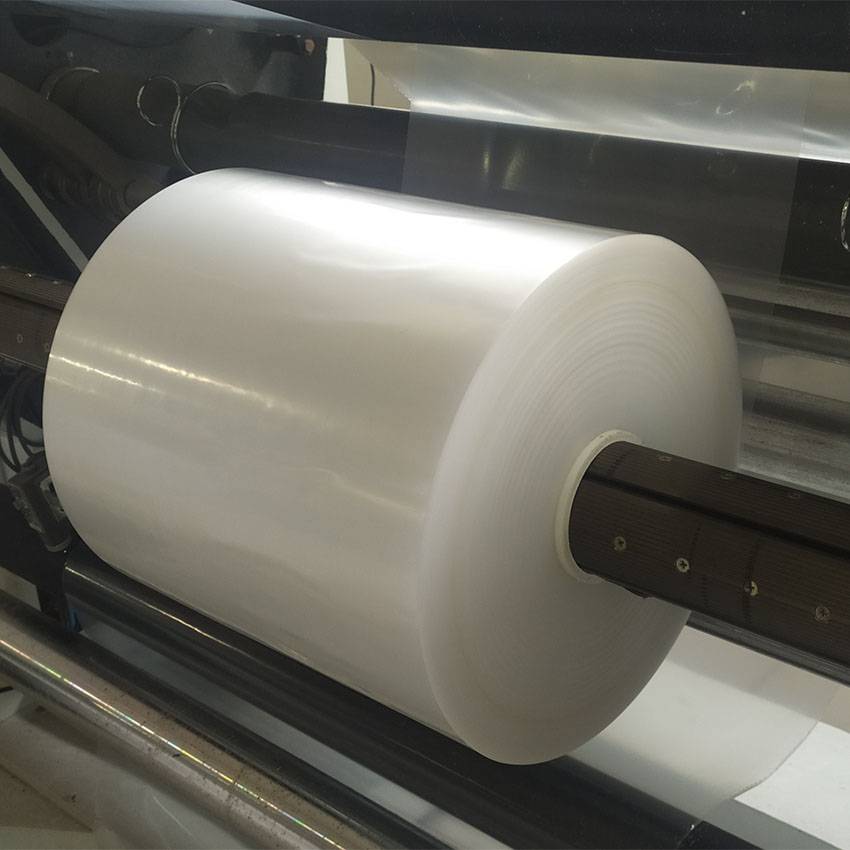

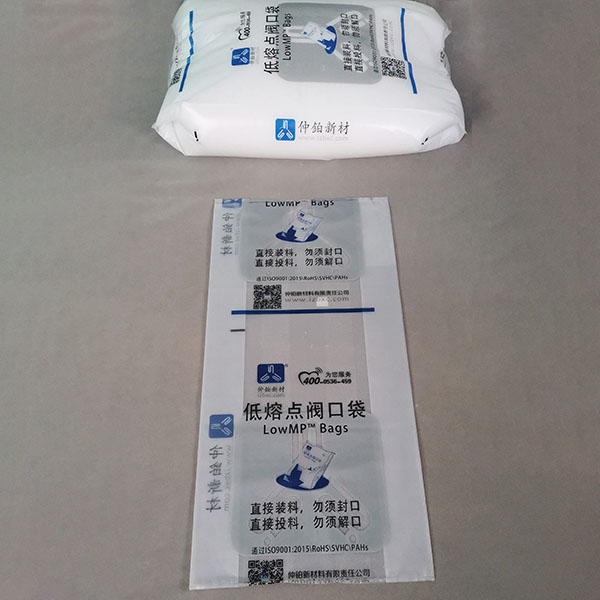

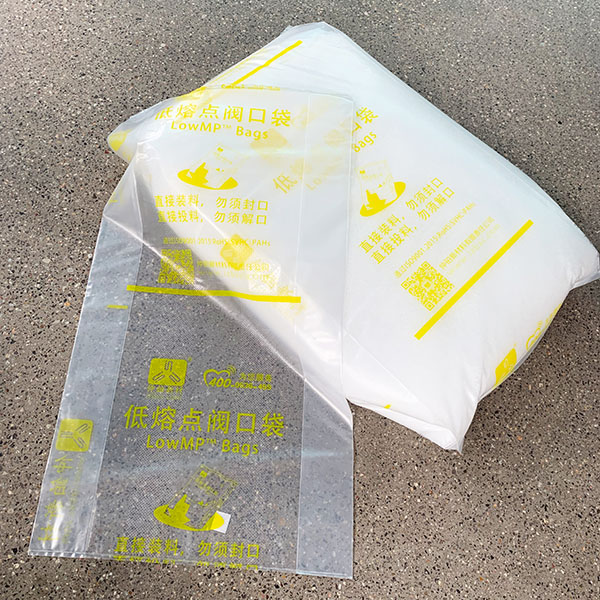

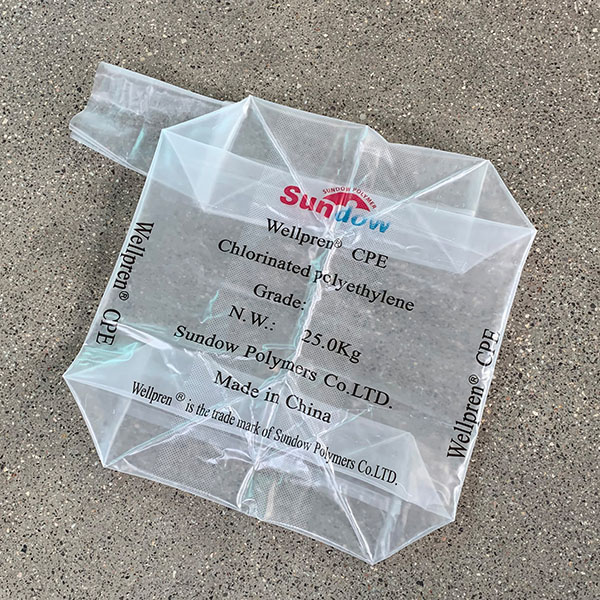

Rubber additives in form of powder or granule include carbon black, white carbon black, zinc oxide, and calcium carbonate are usually packed in kraft paper bags. The paper bags are easy to break during transportation and difficult to dispose after used. To solve these problems, we have specially developed low melt valve bags for rubber additives manufacturers. These bags together with the materials contained can be direct put into an internal mixer because they can easily melt and fully disperse into the rubber compounds as a minor effective ingredient. Different melting points (65-110 deg. C) are available for different application conditions.

BENEFITS:

- No fly loss of materials

- Improve packing efficiency

- Easy piling up and handling of materials

- Assure accurate adding of materials

- Cleaner work environment

- No need for disposal of packaging waste

APPLICATIONS:

- rubber, CPE, carbon black, silica, zinc oxide, alumina, calcium carbonate, kaolinite clay, rubber process oil

OPTIONS:

Bag size, color, embossing, venting, printing

Product detail pictures:

Related Product Guide:

The corporation keeps to the operation concept "scientific management, superior quality and performance primacy, consumer supreme for High reputation - Low Melt Valve Bags for Rubber Additives – Zonpak, The product will supply to all over the world, such as: Cambodia , Indonesia , Barbados , Our company will adhere to "Quality first, , perfection forever, people-oriented , technology innovation"business philosophy. Hard work to keep making progress, innovation in the industry, make every effort to first-class enterprise. We try our best to build the scientific management model, to learn abundant skilled knowledge, to develop advanced production equipment and production process , to create the first-call quality solutions, reasonable price , high quality of service , quick delivery , to offer you create new value .

Production management mechanism is completed, quality is guaranteed, high credibility and service let the cooperation is easy, perfect!