High Quality Low Melt Bags - Low Melt Batch Inclusion Bags – Zonpak

High Quality Low Melt Bags - Low Melt Batch Inclusion Bags – Zonpak Detail:

It is common that dust of raw materials flies everywhere in the workshop of rubber and tire plants, which causes harm to the workers’ health and pollution to the production environment. To solve this problem, low melt batch inclusion bags were developed after lots of material analysis and experiments. With particular low melting points the bags are specially designed for the rubber or plastic compounding and mixing process. Workers can use these bags to pre-weigh and temporarily store the ingredients and additives. In the mixing process, the bags together with the materials contained can be direct put into a mixing machine as the quality of the final product will not be compromised. The using of the low melting batch inclusion bags largely improves the production environment, minimizes the worker exposure to hazardous materials, makes the weighing of the materials easier and increases the production efficiency.

Properties:

The bags are of specific low melting points 65-110 degree Celsius. Different melting points are available according to customers’ requirement. The bags can be direct put into a mill or mixer due to its good meltability and dispersity in rubber and plastic compounds.

The bags have good tensile strength, impact strength, puncture resistance, flexibility, and rubber-like elasticity.

The bags have good chemical stability, no toxicity, excellent environmental stress cracking resistance, weather resistance and compatibility with the rubber materials. The bags can be compatibly blended with natural rubber, styrene butadiene rubber (SBR), butadiene rubber (BR), solution polymerized butadiene styrene rubber (SSBR), polyisoprene rubber, high styrene resin and many other resins, without affecting the physical and chemical properties of the rubber, and it can be used as an active ingredient of the rubber formula, reducing the production cost and packaging waste.

Applications:

These bags are mainly used for packaging various chemical materials and reagents (e.g. white black carbon, black carbon, anti-aging agent, accelerator, sulphur and aromatic hydrocarbon oil) in the rubber industry (manufacture of tire, hose, belt, cable, seals, shoes), plastic processing industry (PVC, plastic pipe and extrude ) and rubber and plastic additives industry.

|

Technical Standards |

|

| Melting point | 65-110 deg. C |

| Physical properties | |

| Tensile strength | MD ≥16MPa TD ≥16MPa |

| Elongation at break | MD ≥400% TD ≥400% |

| Modulus at 100% elongation | MD ≥6MPa TD ≥3MPa |

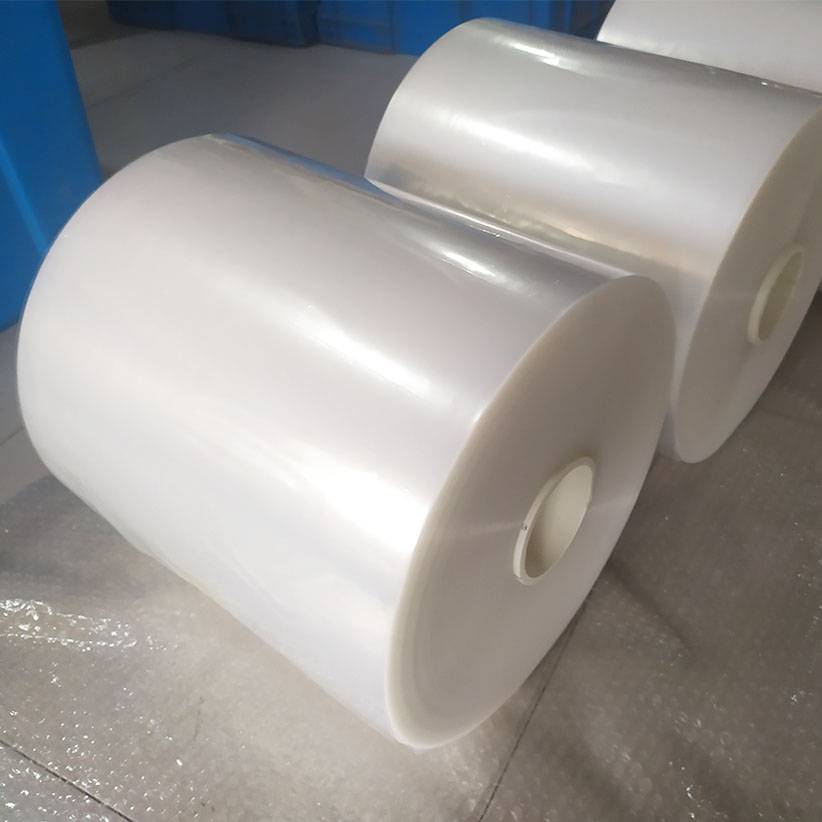

| Appearance | |

| Surface of the product is flat and smooth, there is no wrinkle, no bubble. | |

Product detail pictures:

Related Product Guide:

Our business puts emphasis on the administration, the introduction of talented personnel, as well as the construction of team building, trying hard to further improve the standard and liability consciousness of staff members customers. Our enterprise successfully attained IS9001 Certification and European CE Certification of High Quality Low Melt Bags - Low Melt Batch Inclusion Bags – Zonpak, The product will supply to all over the world, such as: Muscat , Honduras , Uganda , Besides strong technical strength, we also introduce advanced equipment for inspection and conduct strict management. All the staff of our company welcome friends both at home and abroad to come for visits and business on the basis of equality and mutual benefit. If you are interested in any of our items, please feel free to contact us for quotation and product details.

Adhering to the business principle of mutual benefits, we have a happy and successful transaction, we think we will be the best business partner.