High Quality for Heavy Duty EVA Bags - Low Melt EVA Bags – Zonpak

High Quality for Heavy Duty EVA Bags - Low Melt EVA Bags – Zonpak Detail:

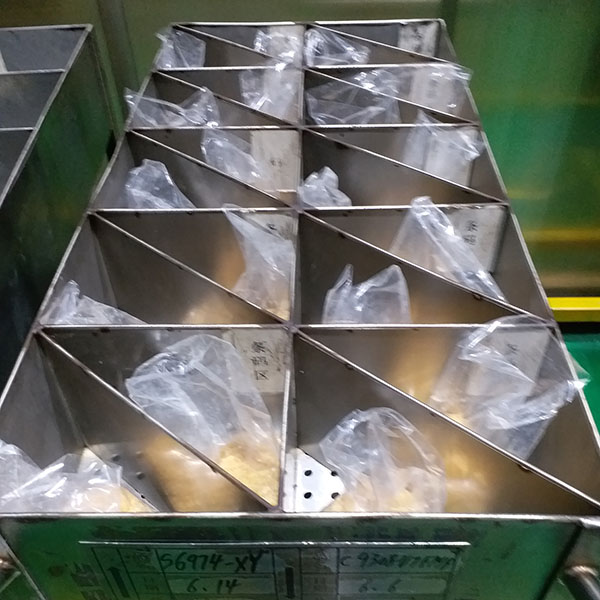

Low melt EVA bags (also called batch inclusion bags) are specially designed packaging bags for rubber ingredients and chemicals used in the rubber and plastic compounding process. The compounding materials can be pre-weighed and temporarily stored in these bags before mixing. Due to the property of low melting point and good compatibility with natural and synthetic rubber, the bags together with the materials inside can be direct put into an internal mixer, and the bags will melt and fully disperse in the rubber or plastic as a minor ingredient.

BENEFITS:

- Assure accurate adding of additives and chemicals

- Make pre-weighing and storing of materials easy

- Provide cleaner mixing area

- Prevent spill loss of additives and chemicals

- Reduce workers’ exposure to the harmful materials

- Leave no packaging waste

APPLICATIONS:

- carbon black, silica (white carbon black), titanium dioxide, anti-aging agent, accelerator, curing agent and rubber process oil

OPTIONS:

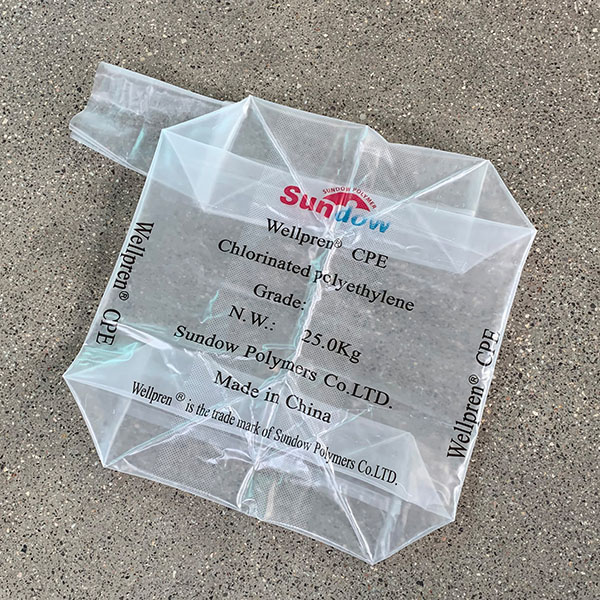

- colour, printing, bag tie

SPECIFICATION:

- Material: EVA

- Melting point: 65-110 deg. C

- Film thickness: 30-100 micron

- Bag width: 150-1200 mm

- Bag length: 200-1500mm

Product detail pictures:

Related Product Guide:

We strive for excellence, service the customers", hopes to become the best cooperation team and dominator enterprise for personnel, suppliers and customers, realizes value share and continuous promotion for High Quality for Heavy Duty EVA Bags - Low Melt EVA Bags – Zonpak, The product will supply to all over the world, such as: Jamaica , Armenia , Palestine , We focus on providing service for our clients as a key element in strengthening our long-term relationships. Our continual availability of high grade products in combination with our excellent pre-sale and after-sales service ensures strong competitiveness in an increasingly globalized market.

The manufacturer gave us a big discount under the premise of ensuring the quality of products, thank you very much, we will select this company again.