Good Quality Low Melt EVA Film - Low Melting Point EVA Film – Zonpak

Good Quality Low Melt EVA Film - Low Melting Point EVA Film – Zonpak Detail:

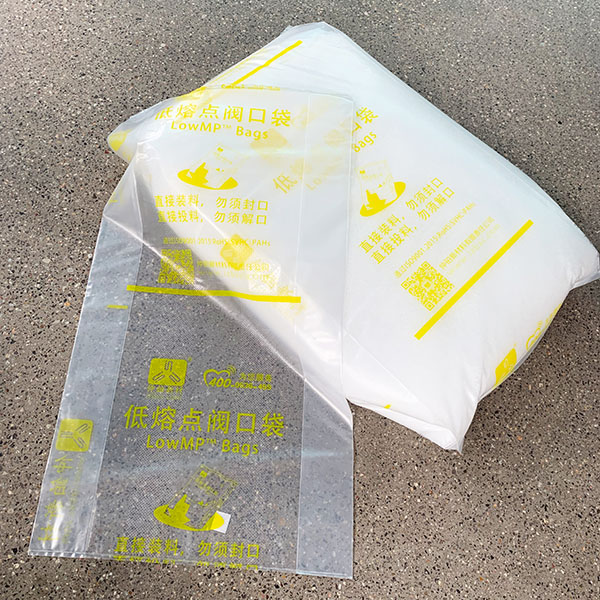

ZonpakTM low melting point EVA film is a special kind of packaging film which can be used on a form-fill-seal (FFS) bagging machine to make little bags of rubber additives (e.g. 100g-5000g). The bags of additives can be direct put into an internal mixer during rubber mixing process. Bags made of the film can easily melt and fully disperse into the rubber as a minor ingredient.

PROPERTIES:

- A wide range of melting points are available for different applications.

- Stable chemical properties, fits most rubber chemicals.

- Good physical strength, suitable for most automatic bagging machines.

- Eliminate the disposal of packaging waste for the material users.

- Helps material users raise work efficiency while decrease waste of materials.

APPLICATIONS:

- peptizer, anti-aging agent, curing agent, aromatic hydrocarbon oil

|

Technical Standards |

|

| Melting point | 65-110 deg. C |

| Physical properties | |

| Tensile strength | MD ≥16MPa TD ≥16MPa |

| Elongation at break | MD ≥400% TD ≥400% |

| Modulus at 100% elongation | MD ≥6MPa TD ≥3MPa |

| Appearance | |

| Surface of the product is flat and smooth, there is no wrinkle, no bubble. | |

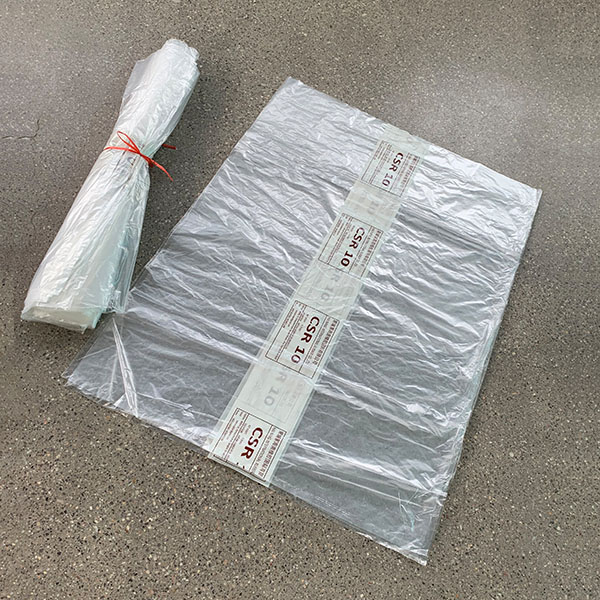

Product detail pictures:

Related Product Guide:

We've numerous great employees customers excellent at promoting, QC, and working with kinds of troublesome difficulty inside the generation method for Good Quality Low Melt EVA Film - Low Melting Point EVA Film – Zonpak, The product will supply to all over the world, such as: Belgium , Juventus , Mongolia , We have the best products and professional sales and technical team.With the development of our company, we are able to provide customers best products, good technical support, perfect after-sales service.

Products and services are very good, our leader is very satisfied with this procurement, it is better than we expected,