Good Quality Low Melt EVA Bags - Batch Inclusion Bags – Zonpak

Good Quality Low Melt EVA Bags - Batch Inclusion Bags – Zonpak Detail:

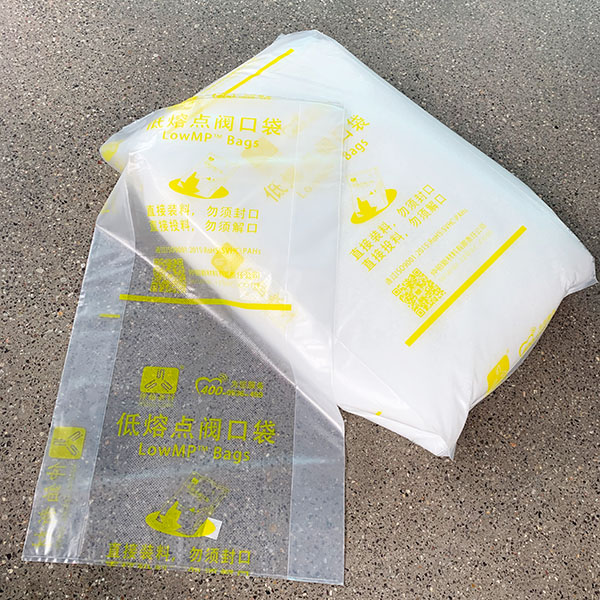

Batch inclusion bags are designed for packaging compounding ingredients in rubber or plastic mixing process to improve the batch uniformity. Bags with different melting points are suitable for different mixing conditions. Due to their low melting point and good compatibility with rubber, the bags together with the chemicals or additives inside can be direct put into a mixer. The bags can easily melt and fully disperse into the rubber as a minor ingredient.

Using batch inclusion bags can help rubber plants improve batch uniformity, provide cleaner work environment, save expensive additives, and increase work efficiency. Bags of different melting points, sizes, thickness, and colors are available to meet the customers’ requirement.

|

Technical Standards |

|

| Melting point | 65-110 deg. C |

| Physical properties | |

| Tensile strength | MD ≥16MPa TD ≥16MPa |

| Elongation at break | MD ≥400% TD ≥400% |

| Modulus at 100% elongation | MD ≥6MPa TD ≥3MPa |

| Appearance | |

| Surface of the product is flat and smooth, there is no wrinkle, no bubble. | |

Product detail pictures:

Related Product Guide:

Having a sound small business credit score, outstanding after-sales services and modern manufacturing facilities, we've got earned an fantastic reputation among our buyers across the globe for Good Quality Low Melt EVA Bags - Batch Inclusion Bags – Zonpak, The product will supply to all over the world, such as: Amman, French , Vietnam , We've been adhering to the philosophy of "attracting customers with the best items and excellent service". We welcome customers, business associations and friends from all parts of the world to contact us and seek cooperation for mutual benefits.

The factory technical staff gave us a lot of good advice in the cooperation process, this is very good, we are very grateful.