Good quality Low Melt Bags For Rubber Conveyer Belt Manufacture - Low Melt Batch Inclusion Bags – Zonpak

Good quality Low Melt Bags For Rubber Conveyer Belt Manufacture - Low Melt Batch Inclusion Bags – Zonpak Detail:

With particular low melting points and good compatibility with rubber and plastics, the EVA batch inclusion bags are specially designed for the rubber or plastic compounding process. The bags are used to pre-weigh and temporarily store the rubber ingredients and additives, and they can be direct thrown into a banbury mixer during compounding process. Using low melting batch inclusion bags can help ensure accurater adding of chemicals, keep the mixing area clean, minimizes the worker exposure to harmful materials and increases the compounding efficiency.

PROPERTIES:

1. Different melting points (from 70 to 110 deg. C) are available as required.

2. Good physical strength, such as high tensile strength, impact strength, puncture resistance, flexibility, and rubber-like elasticity.

3. Excellent chemical stability, nontoxic, good environmental stress cracking resistance, weather resistance and compatibility with most rubber e.g. NR, BR, SBR, SSBR.

APPLICATIONS:

Various rubber chemicals and additives (e.g. carbon black, silica, anti-aging agent, accelerator, curing agent and rubber process oil

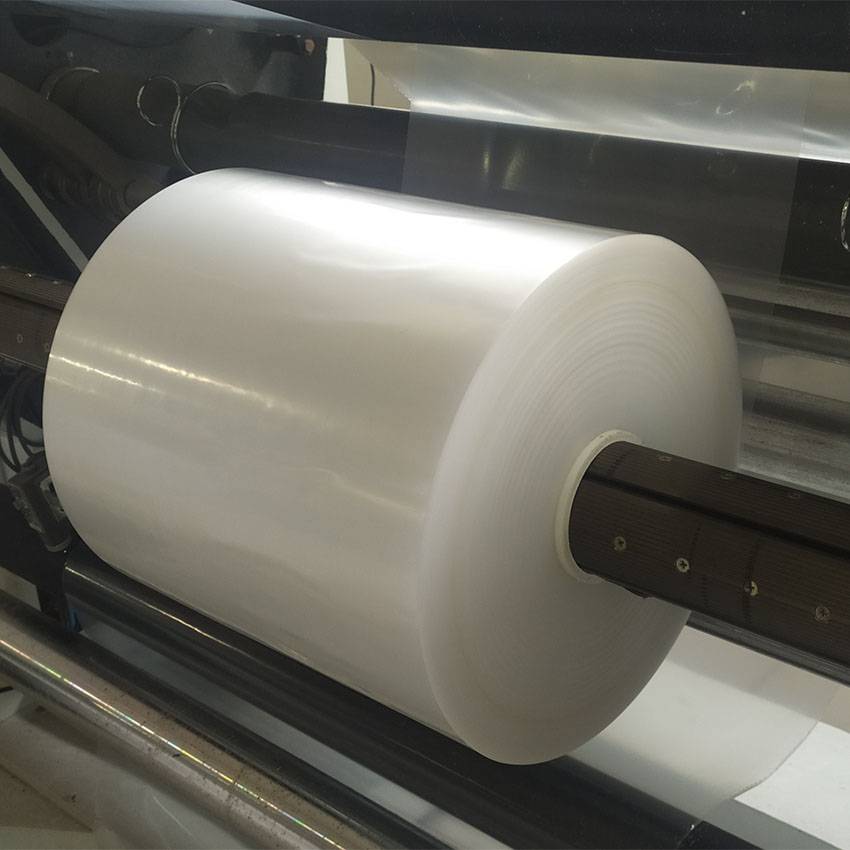

Product detail pictures:

Related Product Guide:

From the past few years, our firm absorbed and digested sophisticated technologies equally at home and abroad. Meanwhile, our organization staffs a group of experts devoted into the growth of Good quality Low Melt Bags For Rubber Conveyer Belt Manufacture - Low Melt Batch Inclusion Bags – Zonpak, The product will supply to all over the world, such as: Madras , Angola , Botswana , So far our merchandise have been exported to east Europe, the Middle East, Southeast, Africa and South America etc. We have now 13years experienced sales and purchase in Isuzu parts at home and abroad and the ownership of the modernized electronic Isuzu parts checking systems. We honor our core principal of Honesty in business, priority in service and will do our best to provide our customers with high quality items and excellent service.

In our cooperated wholesalers, this company has the best quality and reasonable price, they are our first choice.