Good quality - Batch Inclusion Valve Bags – Zonpak

Good quality - Batch Inclusion Valve Bags – Zonpak Detail:

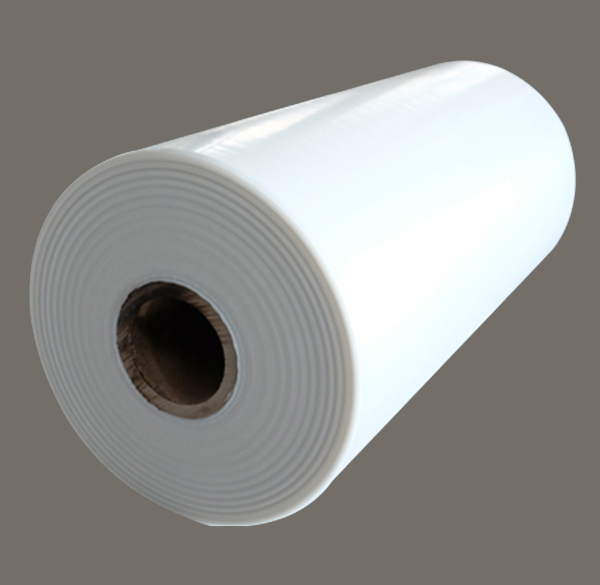

ZonpakTM batch inclusion valve bags are specially designed for packaging rubber additives and other plastic materials in form of powder and granule. With the low melt valve bag and automatic filling machines, rubber additives manufacturers can make product packages of 5kg-25kg. Using the bags can eliminate the fly loss of the material when filling, and there is no need for sealing, so it can largely improve the packaging efficiency.

The bags are made from EVA resin and featured with specific low melting point and excellent compatibility with rubber, so the bags together with the contained materials can be direct put into a mixer, and the bags can fully disperse into the rubber or plastic as a minor ingredient. Different melting points (65-110 deg. C) are available for different application conditions. With uniform packages (5kg, 10kg, 25kg) and no need to unpack before using the materials, the low melt valve bags facilitate the work of the material users as well.

Side gusset and block bottom forms are available. Bag size, thickness, color, embossing, venting and printing can be customized according to customers’ specific requirement.

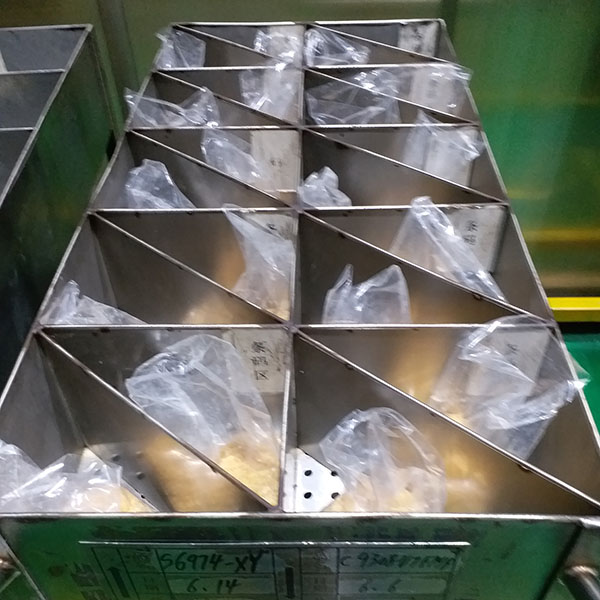

Product detail pictures:

Related Product Guide:

We keep on with the theory of "quality first, provider initially, constant improvement and innovation to meet the customers" with the management and "zero defect, zero complaints" as the standard objective. To great our company, we deliver the merchandise using the fantastic excellent at the reasonable price for Good quality - Batch Inclusion Valve Bags – Zonpak, The product will supply to all over the world, such as: Mexico , London , Jamaica , We are very responsible for all details on our customers order no matter on warranty quality, satisfied prices, quick delivery, on time communication, satisfied packing, easy payment terms, best shipment terms, after sales service etc. We provide one-stop service and best reliability to our every customers. We work hard with our customers, colleagues, workers to make a better future.

We are long-term partners, there is no disappointment every time, we hope to maintain this friendship later!