Free sample for EVA Bag Company - Low Melt Bags for Rubber Seals and Shock Absorber Industry – Zonpak

Free sample for EVA Bag Company - Low Melt Bags for Rubber Seals and Shock Absorber Industry – Zonpak Detail:

Rubber sealants and shock absorbers are widely used in the automotive industry. And rubber mixing is an important process in the production of sealants and bumper. ZonpakTM low melt batch inclusion bags are specially designed for the packaging of rubber ingredients and chemicals used in the rubber compounding and mixing process to improve the batch uniformity. The bags together with the materials contained can be direct put into a mixer, and the bags can easily melt and disperse into the compounds as a minor ingredient.

Main benefits of using the low melt bags:

- Ensure accurate adding of ingredients and chemicals.

- Eliminate fly loss and spill of materials.

- Keep the mixing area clean.

- Save time and increase production efficiency.

- Bag size and color can be customized at request.

|

Technical Standards |

|

| Melting point | 65-110 deg. C |

| Physical properties | |

| Tensile strength | MD ≥16MPa TD ≥16MPa |

| Elongation at break | MD ≥400% TD ≥400% |

| Modulus at 100% elongation | MD ≥6MPa TD ≥3MPa |

| Appearance | |

| Surface of the product is flat and smooth, there is no wrinkle, no bubble. | |

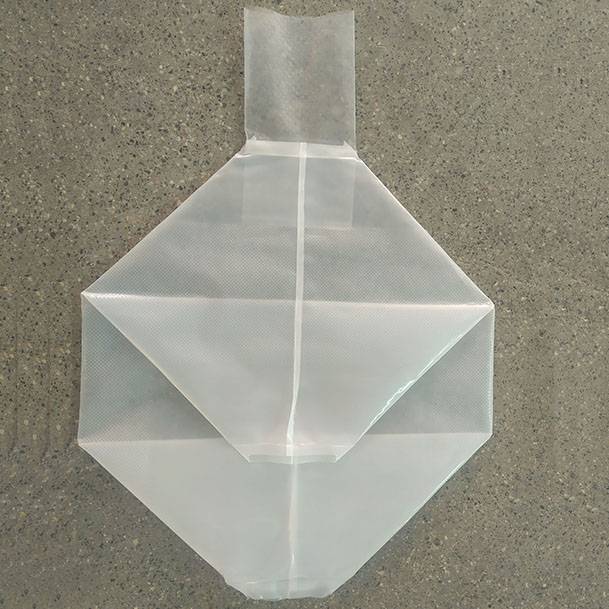

Product detail pictures:

Related Product Guide:

Being supported by an highly developed and specialist IT team, we could give technical support on pre-sales & after-sales service for Free sample for EVA Bag Company - Low Melt Bags for Rubber Seals and Shock Absorber Industry – Zonpak, The product will supply to all over the world, such as: Madagascar , Mexico , Ecuador , The best and original quality for spare parts is a most important factor for transportation. We may stick on supplying original and good quality parts even a little profit earned. God will bless us to do kindness business forever.

The company has rich resources, advanced machinery, experienced workers and excellent services, hope you keep improving and perfecting your products and service, wish you better!