Factory wholesale - Low Melt Valve Bags – Zonpak

Factory wholesale - Low Melt Valve Bags – Zonpak Detail:

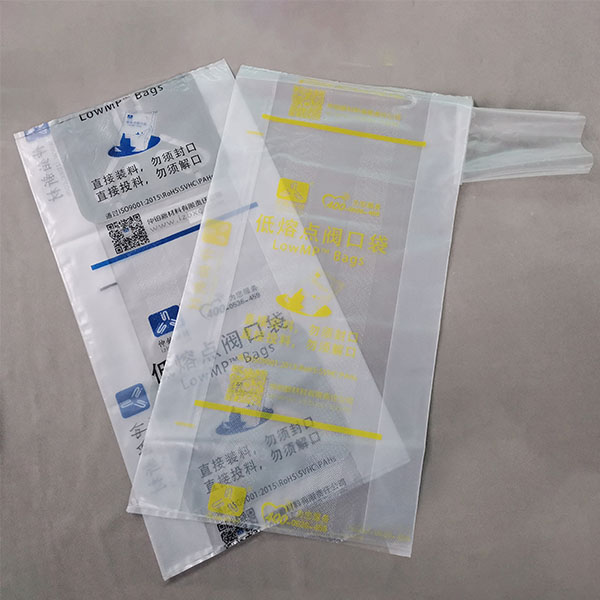

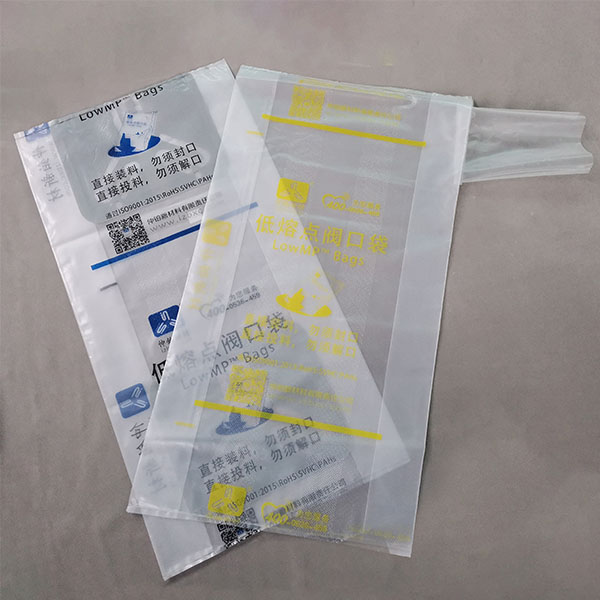

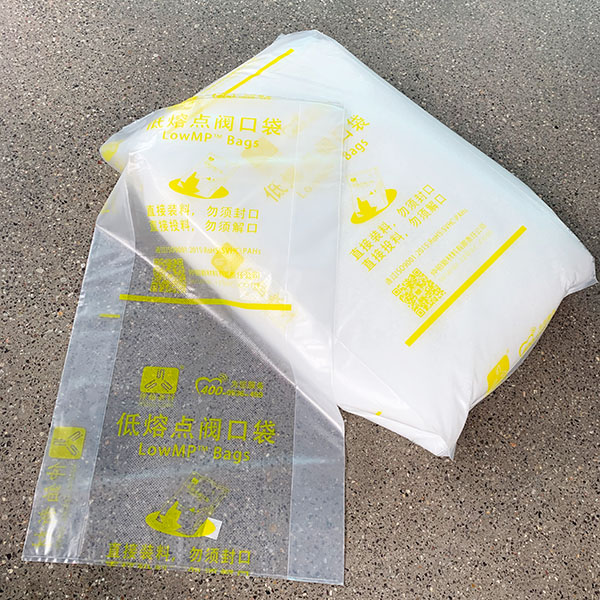

Low melt valve bags are specially designed for the industrial packaging of rubber and plastic additives. Using the low melt valve bags with an automatic filling machine, material suppliers can make standard packages e.g. 5kg, 10kg, 20kg and 25kg which can be direct put into an internal mixer by the material users. The bags will melt and fully disperse in the rubber or plastic mixture as a minor effective ingredient in the compounding and mixing process. So it is more popular than paper bags.

BENEFITS:

- No fly loss of materials

- Improved packing efficiency

- Easy stacking and palletizing

- Assure accurate adding of materials

- Cleaner work environment

- No packaging waste left

APPLICATIONS:

- rubber and plastic pellet or powder, carbon black, silica, zinc oxide, alumina, calcium carbonate, kaolinite clay

OPTIONS:

- Gusset or block bottom, embossing, venting, color, printing

SPECIFICATION:

- Material: EVA

- Melting point available: 72, 85, and 100 deg. C

- Film thickness: 100-200 micron

- Bag width: 350-1000 mm

- Bag length: 400-1500 mm

Product detail pictures:

Related Product Guide:

We take "customer-friendly, quality-oriented, integrative, innovative" as objectives. "Truth and honesty" is our administration ideal for Factory wholesale - Low Melt Valve Bags – Zonpak, The product will supply to all over the world, such as: Germany , Mexico , Madagascar , Due to the stability of our items, timely supply and our sincere service, we are able to sell our merchandise not only over the domestic market, but also exported to countries and regions, including the Middle East, Asia, Europe and other countries and regions. At the same time, we also undertake OEM and ODM orders. We will do our best to serve your company, and establish a successful and friendly cooperation with you.

Product quality is good, quality assurance system is complete, every link can inquire and solve the problem timely!