Factory wholesale EVA Plastic Bag - Batch Inclusion Bags – Zonpak

Factory wholesale EVA Plastic Bag - Batch Inclusion Bags – Zonpak Detail:

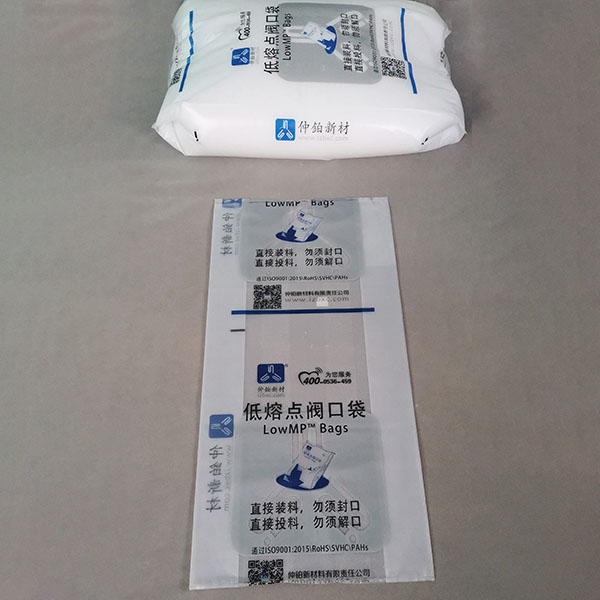

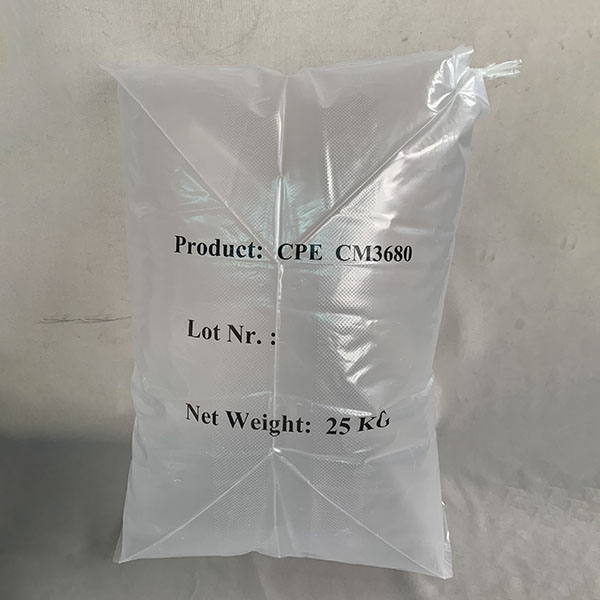

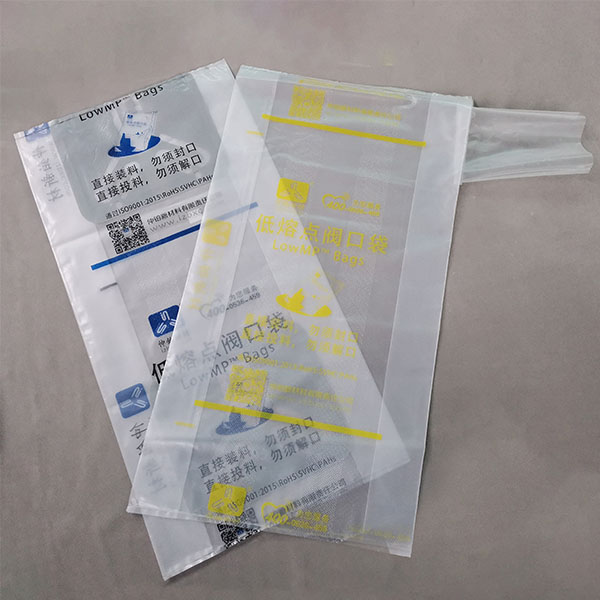

Batch inclusion bags are designed for packaging compounding ingredients in rubber or plastic mixing process to improve the batch uniformity. Bags with different melting points are suitable for different mixing conditions. Due to their low melting point and good compatibility with rubber, the bags together with the chemicals or additives inside can be direct put into a mixer. The bags can easily melt and fully disperse into the rubber as an effective ingredient. Using ZonpakTM batch inclusion bags can help rubber plants improve batch uniformity, provide cleaner work environment, save expensive additives, and raise efficiency.

Bags of different melting points, sizes, thickness, and colors are available to meet the customers’ requirement.

|

Technical Standards |

|

| Melting point | 65-110 deg. C |

| Physical properties | |

| Tensile strength | MD ≥16MPa TD ≥16MPa |

| Elongation at break | MD ≥400% TD ≥400% |

| Modulus at 100% elongation | MD ≥6MPa TD ≥3MPa |

| Appearance | |

| Surface of the product is flat and smooth, there is no wrinkle, no bubble. | |

Product detail pictures:

Related Product Guide:

We've got quite possibly the most state-of-the-art production gear, experienced and qualified engineers and workers, acknowledged top quality handle systems along with a friendly expert gross sales group pre/after-sales support for Factory wholesale EVA Plastic Bag - Batch Inclusion Bags – Zonpak, The product will supply to all over the world, such as: Panama , Chile , Costa rica , Thus far, our item associated with printer dtg a4 may be shown in most foreign nations as well as urban centers, which are sought after simply by targeted traffic. We all highly imagine that now we have now the full capacity to present you with contented merchandise. Desire to collect requests of your stuff and produce the long-term co-operation partnership. We very seriously promise:Csame top quality, better price; exact same selling price, higher quality.

We are really happy to find such a manufacturer that ensuring product quality at the same time the price is very cheap.