Chinese Professional Low Melt Bags For Rubber Additives - Low Melt Bags for Shoes Material Industry – Zonpak

Chinese Professional Low Melt Bags For Rubber Additives - Low Melt Bags for Shoes Material Industry – Zonpak Detail:

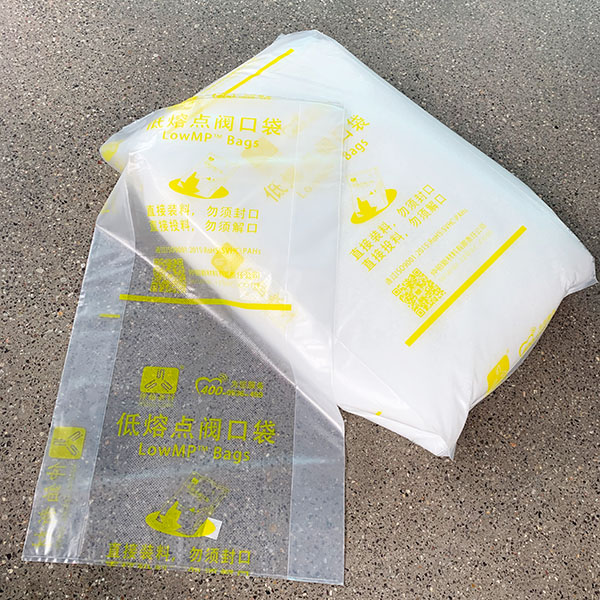

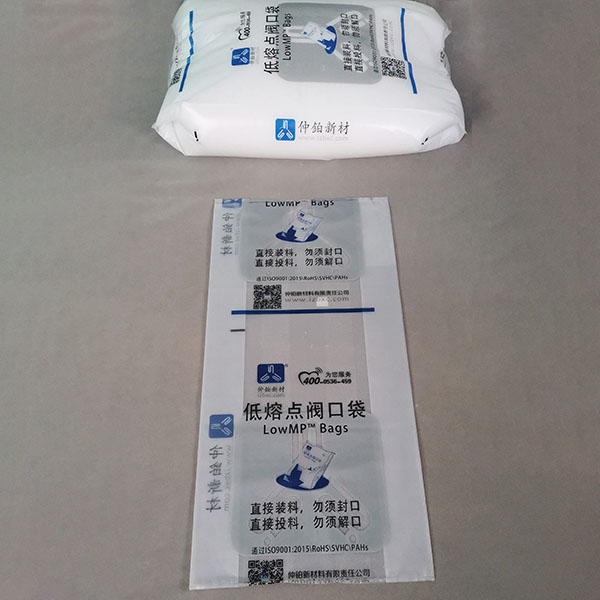

Synthetic rubber is widely used as a sole material for shoes industry. ZonpakTM low melt batch inclusion bags are specially designed for packing the additives used in the rubber compounding process. Due to its low melting point and good compatibility with rubber, the bags together with the additives can be direct put into a mixer or mill. These bags can easily melt and evenly disperse into the rubber as a minor ingredient. Using the low melt batch inclusion bags can help improve work environment, ensure accurate adding of additives, increase production efficiency.

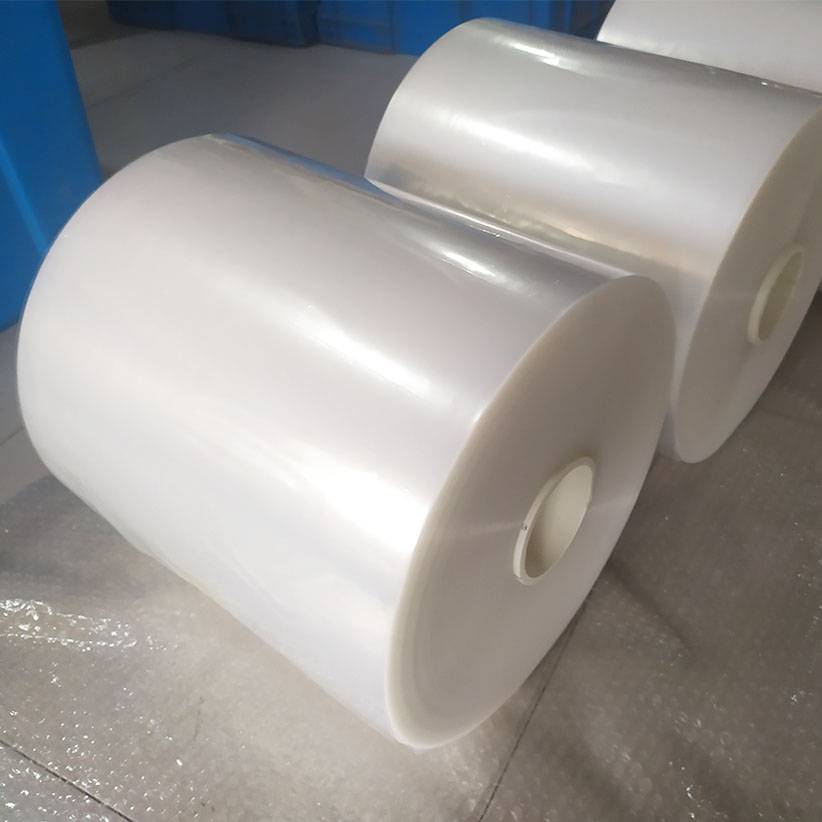

SPECIFICATION:

- Material: EVA

- Melting point: 65-110 deg. C

- Film thickness: 30-100 micron

- Bag width: 200-1200 mm

- Bag length: 300-1500mm

Product detail pictures:

Related Product Guide:

Our company puts emphasis on the management, the introduction of talented personnel, and the construction of staff building, trying hard to improve the quality and liability consciousness of staff members. Our company successfully attained IS9001 Certification and European CE Certification of Chinese Professional Low Melt Bags For Rubber Additives - Low Melt Bags for Shoes Material Industry – Zonpak, The product will supply to all over the world, such as: Slovak Republic , Atlanta , Croatia , Besides there are also experienced production and management , advanced production equipment to assure our quality and delivery time , our company pursues the principle of good faith, high-quality and high-efficiency. We guarantee that our company will try our best to reduce customer purchase cost, shorten the period of purchase, stable solutions quality, increase customers' satisfaction and achieve win-win situation .

This is the first business after our company establish, products and services are very satisfying, we have a good start, we hope to cooperate continuous in the future!