Chinese Professional Low Melt Bags For Rubber Additives - Batch Inclusion Low Melt Bags – Zonpak

Chinese Professional Low Melt Bags For Rubber Additives - Batch Inclusion Low Melt Bags – Zonpak Detail:

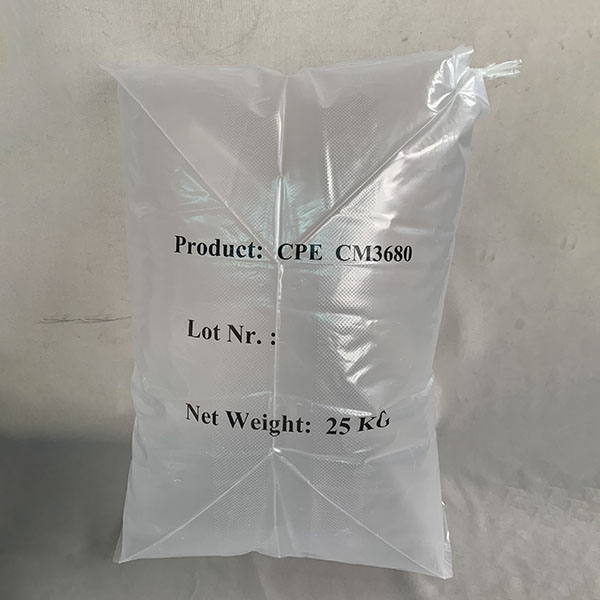

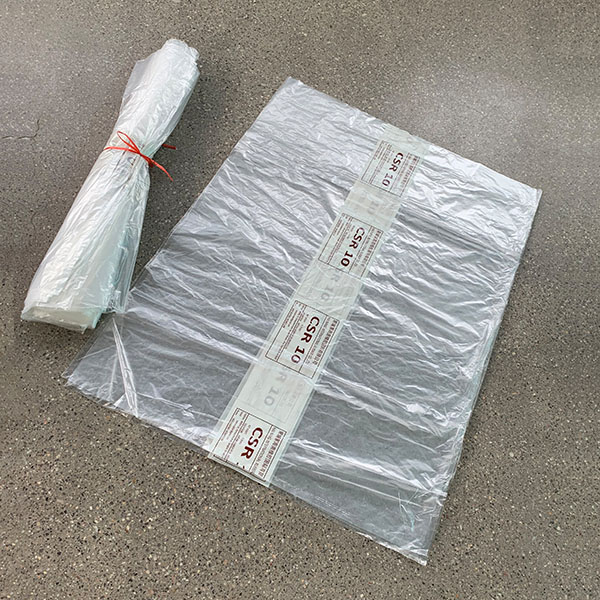

ZonpakTM batch inclusion low melt bags are specially designed industrial packaging bags for rubber ingredients and additives used in the rubber compounding process. As the material of the bags has good compatibility with natural and synthetic rubber, these bags together with the materials contained can be direct put into an internal mixer, and the bags will melt and fully disperse in the rubber as a minor effective ingredient.

BENEFITS:

- Facilitate pre-weighing and handling of the materials.

- Ensure accurate dosage of ingredients, improve batch to batch uniformity.

- Reduce spill losses, prevent material waste.

- Reduce dust fly, provide cleaner work environment.

- Improve the process efficiency, reduce the comprehensive cost.

SPECIFICATION:

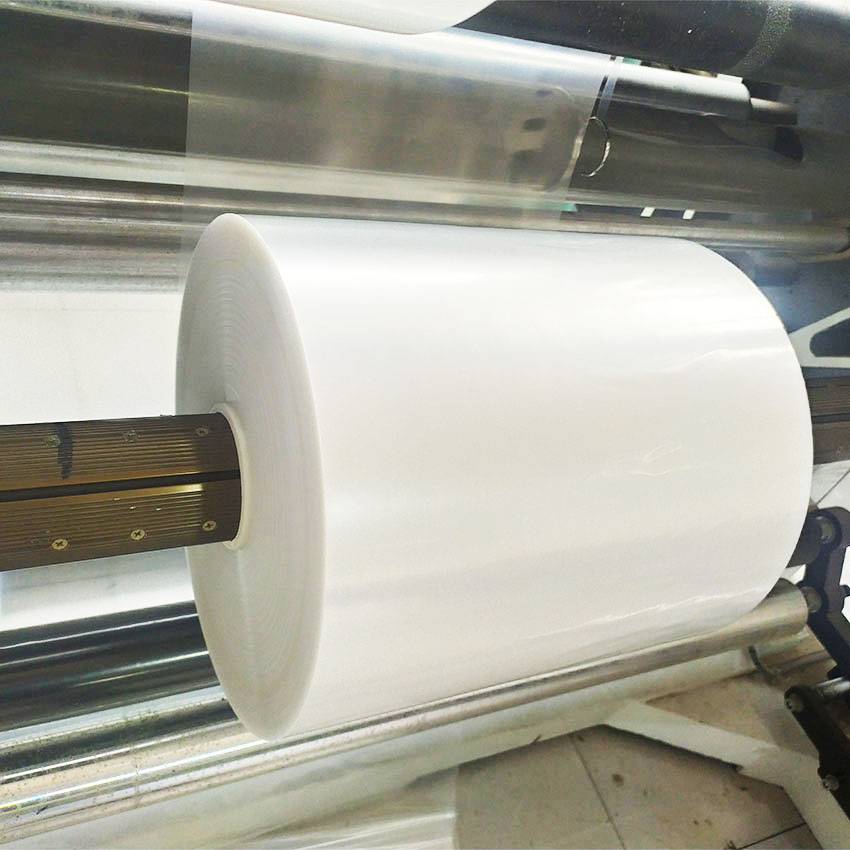

- Material: EVA

- Melting point: 65-110 deg. C

- Film thickness: 30-100 micron

- Bag width: 200-1200 mm

- Bag length: 250-1500mm

Product detail pictures:

Related Product Guide:

With reliable excellent approach, great name and ideal consumer services, the series of products and solutions produced by our company are exported to many countries and regions for Chinese Professional Low Melt Bags For Rubber Additives - Batch Inclusion Low Melt Bags – Zonpak, The product will supply to all over the world, such as: Argentina , Durban , Swedish , Qualified R&D engineer might be there for your consultation service and we will try our best to meet your requirements. So you should feel free to contact us for inquiries. You'll be able to send us emails or call us for small business. Also you are able to come to our business by yourself to get further knowing of us. And we are going to surely present you with the best quotation and after-sale service. We're ready to build stable and friendly relations with our merchants. To achieve mutual success, we'll make our best efforts to build a solid co-operation and transparent communication work with our companions. Above all, we're here to welcome your inquiries for any of our merchandise and service.

After the signing of the contract, we received satisfactory goods in a short term, this is a commendable manufacturer.