Best quality Low Melt Pouch - Low Melt EVA Pouches – Zonpak

Best quality Low Melt Pouch - Low Melt EVA Pouches – Zonpak Detail:

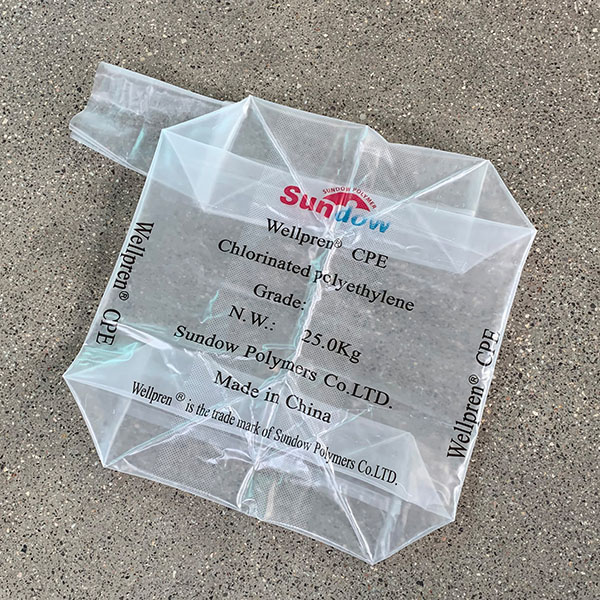

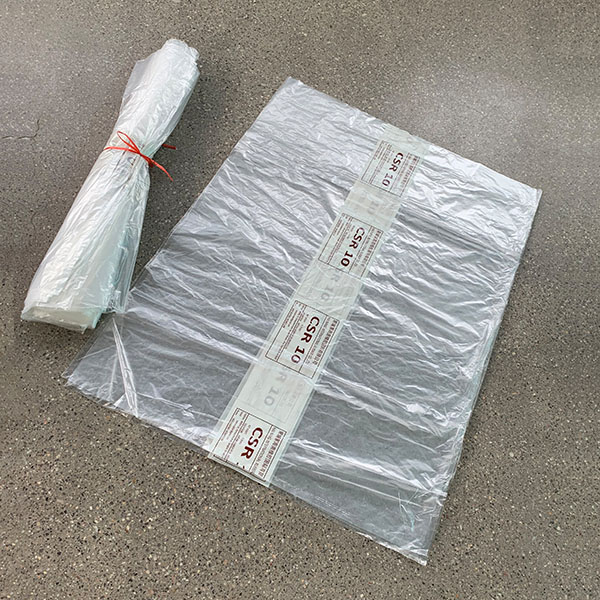

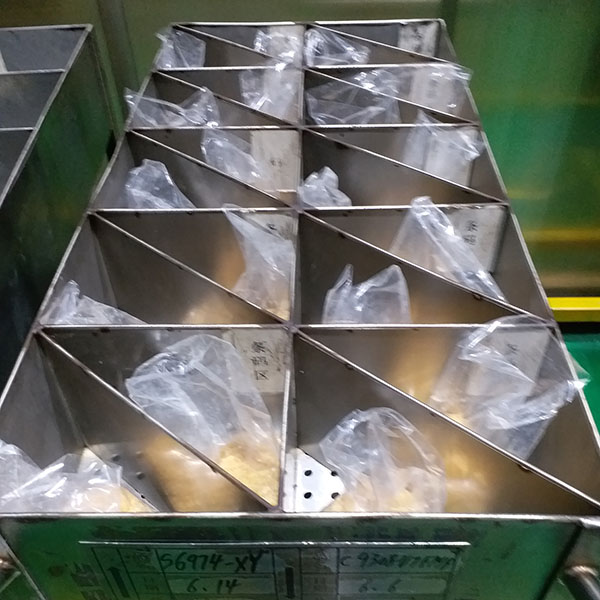

ZonpakTM low melt EVA pouches are made from EVA (Ethylene Vinyl Acetate), and are mainly used to pack rubber compounding ingredients (e.g. liquid aromatic hydrocarbons and powder chemicals) in tire and rubber manufacture process. Due to the property of low melting point and good compatibility with rubber, the pouches together with the additives contained can be direct put into an internal mixer or mill and fully disperse in the rubber as an effective ingredient, so it can provide accurate adding of additives and cleaner work environment. Using the pouches can help rubber plants get uniform rubber compounds, save additives and raise production efficiency.

Melting point, size and color can be customized according to the customers’ specific application requirement.

|

Technical Standards |

|

| Melting point | 65-110 deg. C |

| Physical properties | |

| Tensile strength | MD ≥16MPaTD ≥16MPa |

| Elongation at break | MD ≥400%TD ≥400% |

| Modulus at 100% elongation | MD ≥6MPaTD ≥3MPa |

| Appearance | |

| Surface of the product is flat and smooth, there is no wrinkle, no bubble. | |

Product detail pictures:

Related Product Guide:

We always stick to the principle "Quality First, Prestige Supreme". We are fully committed to providing our clients with competitively priced quality products, prompt delivery and professional service for Best quality Low Melt Pouch - Low Melt EVA Pouches – Zonpak, The product will supply to all over the world, such as: Madagascar , Myanmar , Zimbabwe , Insisting over the high-quality generation line management and prospects guide provider, we've made our resolution to offer our shoppers using the initially stage purchasing and soon after provider working experience. Preserving the prevailing helpful relations with our prospects, we even now innovate our product lists the many time to meet up with the brand new wants and stick to the latest trend of this business in Ahmedabad. We're ready to facial area the difficulties and make the transform to grasp many of the possibilities in international trade.

The company's products very well, we have purchased and cooperated many times, fair price and assured quality, in short, this is a trustworthy company!