Best quality Low Melt Pouch - Low Melt Bags for Rubber Hose Industry – Zonpak

Best quality Low Melt Pouch - Low Melt Bags for Rubber Hose Industry – Zonpak Detail:

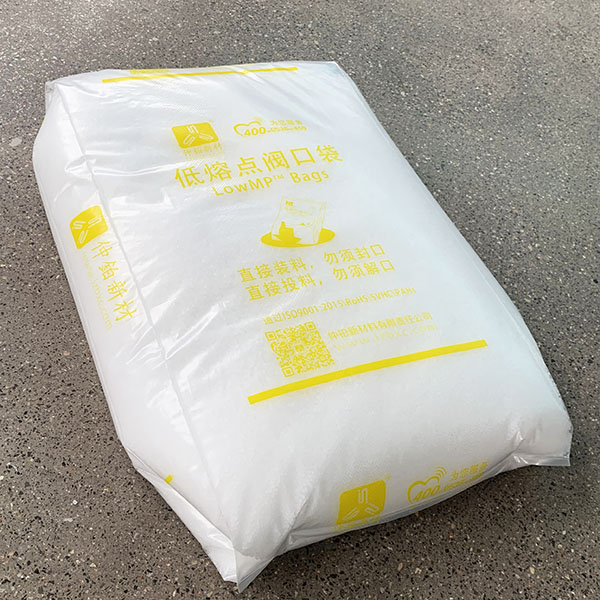

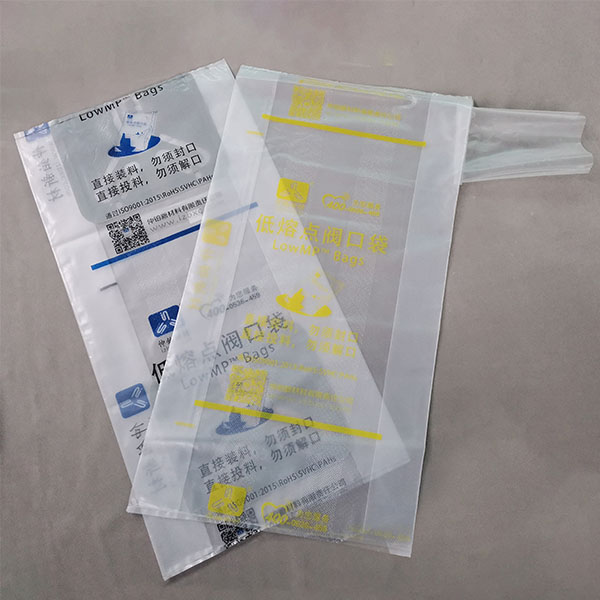

Rubber mixing plays an important role in the production of rubber hose or tube. ZonpakTM low melt EVA batch inclusion bags are designed for packaging the rubber chemicals used in the rubber compounding or mixing process. The main properties of the bags are low melting point and good compatibility with rubber, so the bags together with the additives and chemicals inside can be direct put into an internal mixer. The bags can easily melt and disperse into the rubber as minor effective ingredient. Using the batch inclusion bags can help ensure accurate adding of additives, provide a cleaner work environment, save time and production cost.

Bag size and color can be customized at request.

|

Technical Standards |

|

| Melting point | 65-110 deg. C |

| Physical properties | |

| Tensile strength | MD ≥16MPa TD ≥16MPa |

| Elongation at break | MD ≥400% TD ≥400% |

| Modulus at 100% elongation | MD ≥6MPa TD ≥3MPa |

| Appearance | |

| Surface of the product is flat and smooth, there is no wrinkle, no bubble. | |

Product detail pictures:

Related Product Guide:

We persist with the principle of "quality 1st, assistance initially, continual improvement and innovation to meet the customers" for your management and "zero defect, zero complaints" as the standard objective. To great our service, we present the products and solutions while using the very good top quality at the reasonable cost for Best quality Low Melt Pouch - Low Melt Bags for Rubber Hose Industry – Zonpak, The product will supply to all over the world, such as: Denver , Auckland , Paris , We will do our utmost to cooperate & satisfied with you relying on top-grade quality and competitive price and best after service ,sincerely look forward to cooperating with you and make achievements in the future!

The sales person is professional and responsible, warm and polite, we had a pleasant conversation and no language barriers on communication.