Best Price for Batch Inclusion Low Melt Bags - Low Melt EVA Bags – Zonpak

Best Price for Batch Inclusion Low Melt Bags - Low Melt EVA Bags – Zonpak Detail:

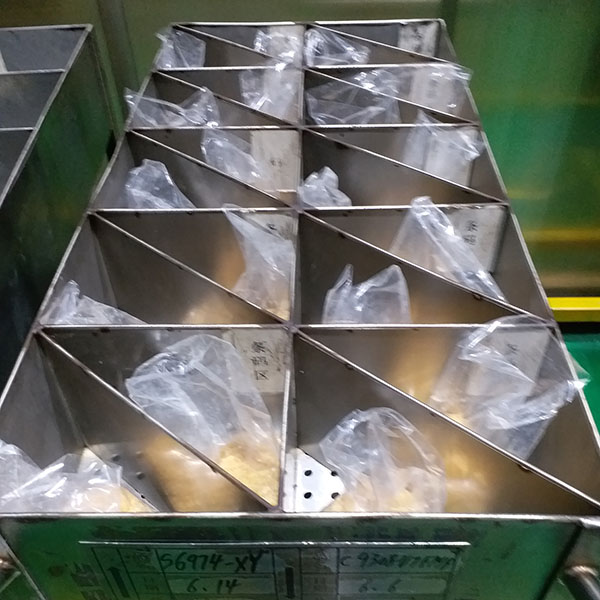

Low melt EVA bags (batch inclusion bags) are specially designed packing bags for rubber ingredients and chemicals used in the rubber and plastic compounding process. The compounding materials can be pre-weighed and temporarily stored in these bags. Due to their property of low melting point and good compatibility with natural and synthetic rubber, the bags together with the materials inside can be direct put into an internal mixer, and the bags will melt and fully disperse in the rubber or plastic as a minor effective ingredient.

BENEFITS:

- Assure accurate adding of additives and chemicals

- Make pre-weighing and storing of materials easy

- Provide clean mixing area

- Decrease waste of additives and chemicals

- Reduce workers’ exposure to the harmful materials

- Leave no packaging waste

APPLICATIONS:

- carbon black, silica (white carbon black), titanium dioxide, anti-aging agent, accelerator, curing agent and rubber process oil

OPTIONS:

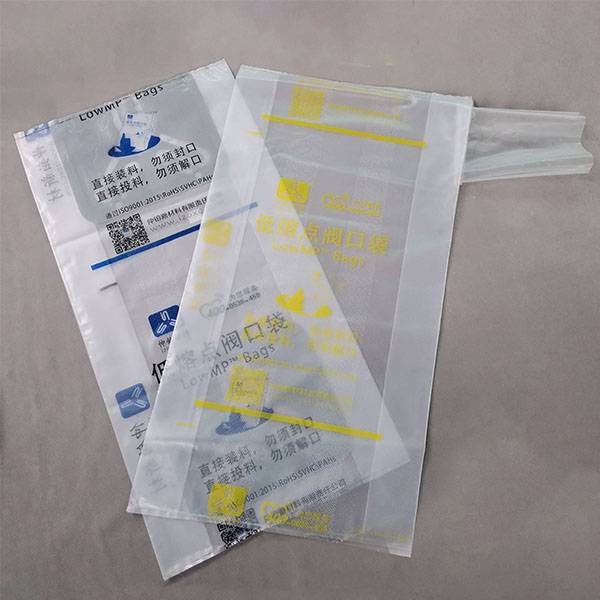

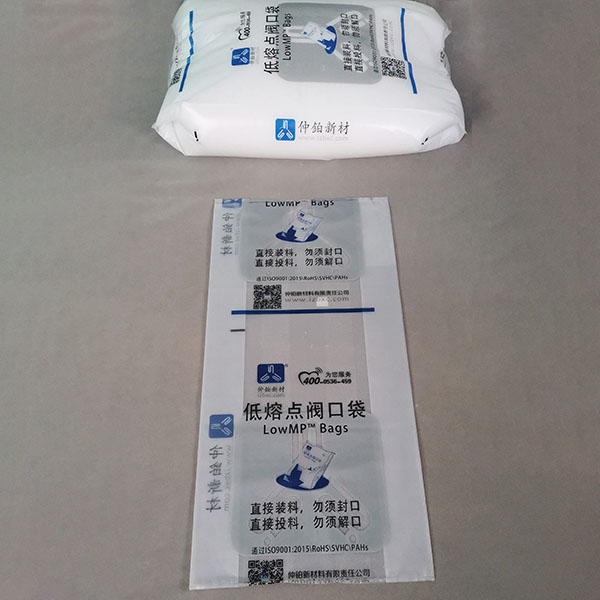

- colour, printing, bag tie

SPECIFICATION:

- Material: EVA

- Melting point: 65-110 deg. C

- Film thickness: 30-100 micron

- Bag width: 150-1200 mm

- Bag length: 200-1500mm

Product detail pictures:

Related Product Guide:

High quality Very first,and Consumer Supreme is our guideline to offer the most beneficial service to our consumers.At present, we're attempting our greatest to be among the top exporters in our area to fulfill buyers far more need to have for Best Price for Batch Inclusion Low Melt Bags - Low Melt EVA Bags – Zonpak, The product will supply to all over the world, such as: Czech republic , Poland , Berlin , The products has a good reputation with competitive price, unique creation, leading the industry trends. The company insists on the principle of win-win idea, has establishedglobal sales network and after-sales service network.

The customer service staff's answer is very meticulous, the most important is that the product quality is very good, and packaged carefully, shipped quickly!