Best Price for Batch Inclusion Low Melt Bags - Low Melt Bags for Rubber Compounding – Zonpak

Best Price for Batch Inclusion Low Melt Bags - Low Melt Bags for Rubber Compounding – Zonpak Detail:

ZonpakTM low melt bags are specially designed for packing rubber ingredients and chemicals used in the rubber compounding process. The materials e.g. black carbon, anti-aging agent, accelerator, curing agent and aromatic hydrocarbon oil can be pre-weighed and temporarily stored in these bags. Due to their good compatibility with natural and synthetic rubber, these bags together with the materials inside can be direct put into an internal mixer, and the bags will melt and fully disperse in the rubber as a minor effective ingredient.

BENEFITS:

- Accurate adding of ingredients and chemicals

- Easy pre-weighing and storing

- Clean mixing area

- No waste of additives and chemicals

- Reduce workers’ exposure to the harmful materials

- Less labor and time needed

SPECIFICATION:

- Material: EVA

- Melting point: 65-110 deg. C

- Film thickness: 30-100 micron

- Bag width: 200-1200 mm

- Bag length: 250-1500mm

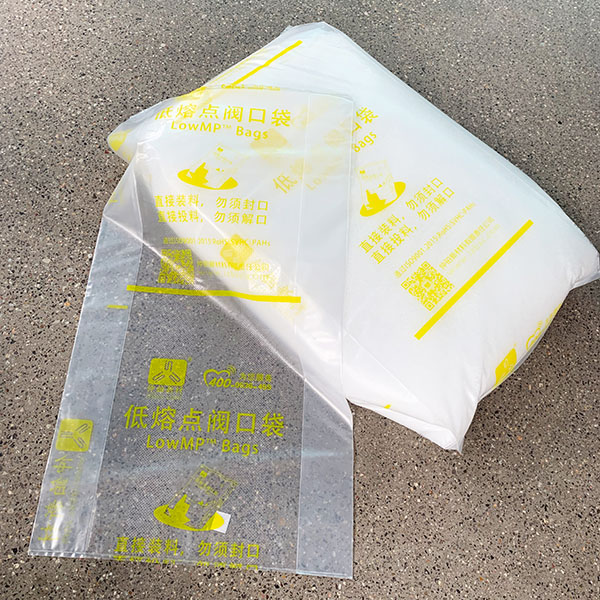

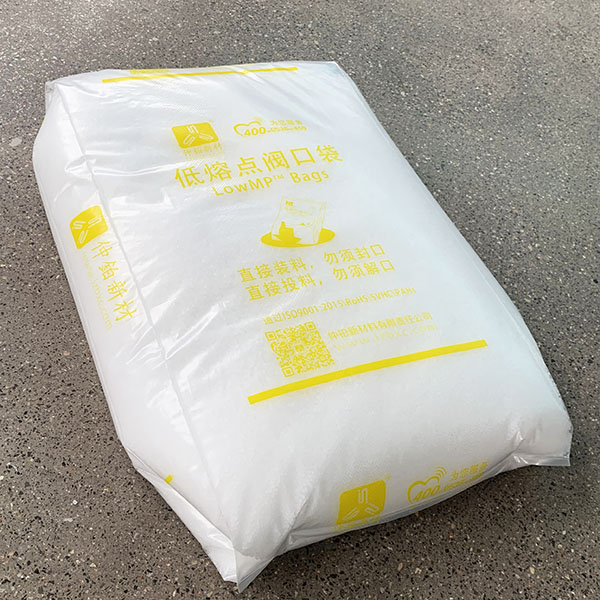

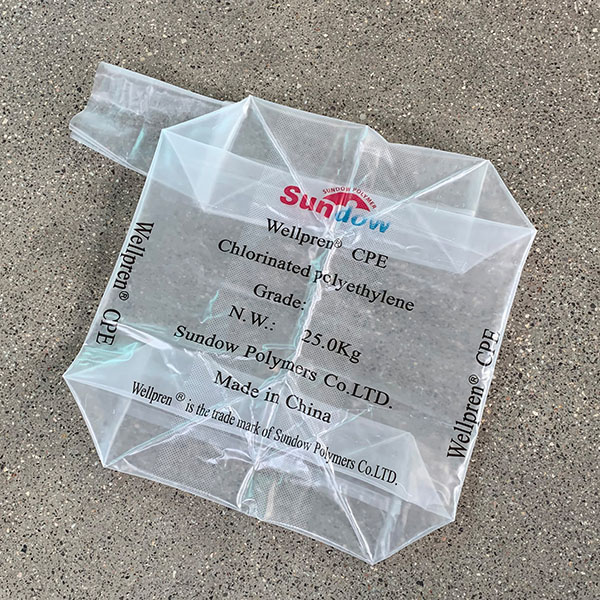

Product detail pictures:

Related Product Guide:

Our advantages are reduced prices,dynamic product sales workforce,specialized QC,solid factories,superior quality services for Best Price for Batch Inclusion Low Melt Bags - Low Melt Bags for Rubber Compounding – Zonpak, The product will supply to all over the world, such as: Iran , Angola , Madrid , Now, we are trying to enter new markets where we do not have a presence and developing the markets we have now the already penetrated. On account of superior quality and competitive price , we'll be the market leader, be sure to don??¥t hesitate to contact us by phone or email, if you are interested in any of our solutions.

The accounts manager made a detailed introduction about the product, so that we have a comprehensive understanding of the product, and ultimately we decided to cooperate.