2019 High quality Low Melting Point Plastic Bags - Low Melt EVA Batch Inclusion Bags – Zonpak

2019 High quality Low Melting Point Plastic Bags - Low Melt EVA Batch Inclusion Bags – Zonpak Detail:

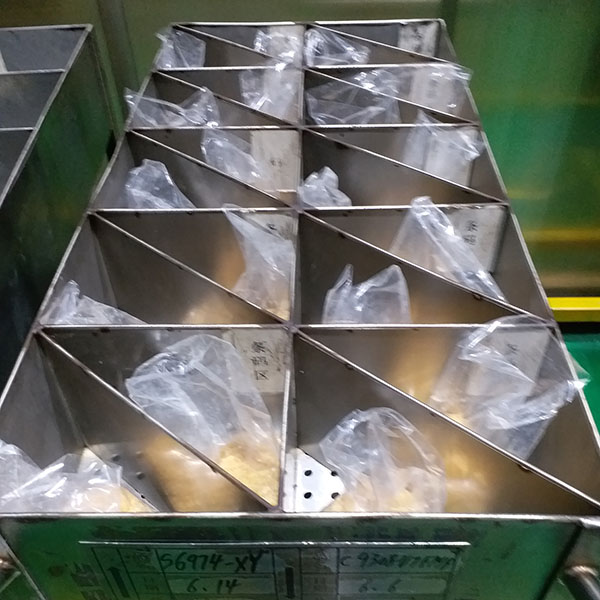

ZonpakTM low melt EVA batch inclusion bags are specially designed packaging or lining bags for rubber ingredients and additives used in the rubber compounding process. As the material of the bags has good compatibility with natural and synthetic rubber, these bags of ingredients can be direct put into a mixer, and the bags will melt and fully disperse in the rubber as an effective ingredient.

BENEFITS:

- Facilitate pre-weighing and handling of the materials.

- Ensure accurate dosage of ingredients, improve batch to batch uniformity.

- Reduce spill losses, prevent material waste.

- Reduce dust fly, provide cleaner work environment.

- Improve the process efficiency, reduce the comprehensive cost.

APPLICATIONS:

- carbon black, silica (white carbon black), titanium dioxide, anti-aging agent, accelerator, curing agent and rubber process oil

OPTIONS:

- colour, bag tie, printing

Product detail pictures:

Related Product Guide:

With advanced technologies and facilities, strict quality control, reasonable price, superior service and close co-operation with customers, we are devoted to providing the best value for our customers for 2019 High quality Low Melting Point Plastic Bags - Low Melt EVA Batch Inclusion Bags – Zonpak, The product will supply to all over the world, such as: Grenada , Lyon , Sri Lanka , After years' creating and developing, with the advantages of trained qualified talents and rich marketing experience, outstanding achievements were gradually made. We get good reputation from the customers due to our good products quality and fine after-sale service. We sincerely wish to create a more prosperous and flourishing future together with all the friends home and abroad!

Hope that the company could stick to the enterprise spirit of "Quality, Efficiency, Innovation and Integrity", it will be better and better in the future.