2019 Good Quality Low Melting Point Ffs Film - FFS Film for Rubber Chemicals – Zonpak

2019 Good Quality Low Melting Point Ffs Film - FFS Film for Rubber Chemicals – Zonpak Detail:

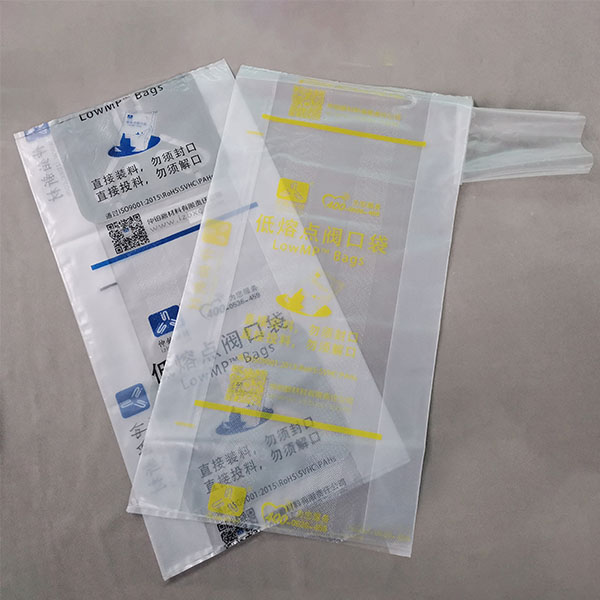

ZonpakTM FFS film is specially designed for the FFS (form-fill-seal) packaging of rubber chemicals. The best feature of the film is low melting point and good compatibility with natural and synthetic rubber. The little bags (100g-5000g) made by FFS machines can be direct put into an internal mixer by the material user as they can easily melt and fully disperse into the rubber compounds as a minor effective ingredient.

This packaging film has stable chemical properties, can fit most rubber chemicals. Good physical strength makes the film suit for most automatic FFS packing machines. Films with different melting points and thickness are available for different using conditions.

APPLICATIONS:

- peptizer, anti-aging agent, curing agent, rubber process oil

OPTIONS:

- single wound or tube, colour, printing

|

Technical Datas |

|

| Melting point | 65-110 deg. C |

| Physical properties | |

| Tensile strength | MD ≥12MPa TD ≥12MPa |

| Elongation at break | MD ≥300% TD ≥300% |

| Modulus at 100% elongation | MD ≥6MPa TD ≥3MPa |

| Appearance | |

| Surface of the product is flat and smooth, there is no wrinkle, no bubble. | |

Product detail pictures:

Related Product Guide:

go on to boost, to be certain item quality in line with market and buyer standard demands. Our firm has a excellent assurance procedure happen to be established for 2019 Good Quality Low Melting Point Ffs Film - FFS Film for Rubber Chemicals – Zonpak, The product will supply to all over the world, such as: Hongkong , Madras , Lahore , We aspire to meet the demands of our customers globally. Our range of merchandise and services is continuously expanding to meet customers' requirements. We welcome new and old customers from all walks of life to contact us for future business relationships and achieving mutual success!

This enterprise in the industry is strong and competitive, advancing with the times and develop sustainable, we are very pleased to have a opportunity to cooperate!