100% Original EVA Side Gusset Bags - Batch Inclusion Bags – Zonpak

100% Original EVA Side Gusset Bags - Batch Inclusion Bags – Zonpak Detail:

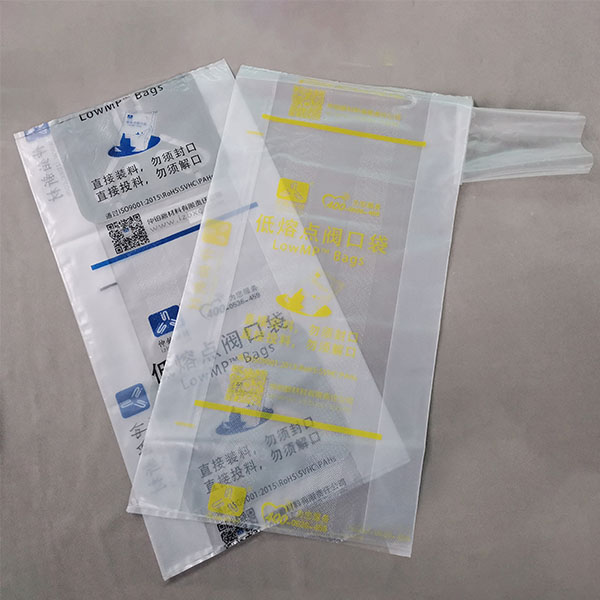

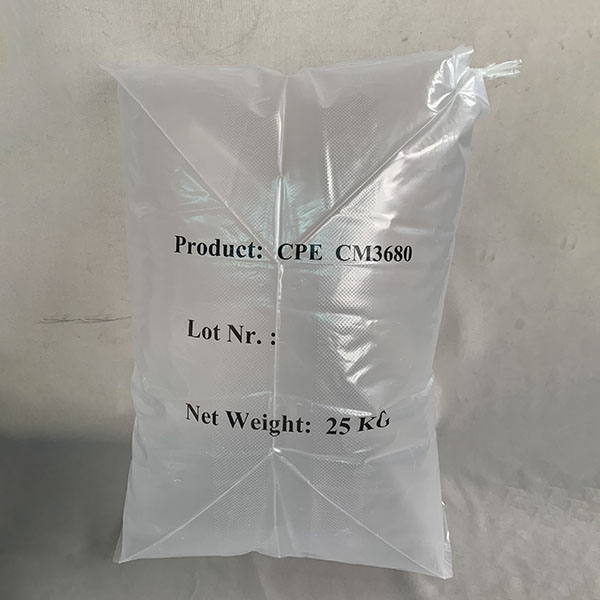

Batch inclusion bags are designed for packaging compounding ingredients in rubber or plastic mixing process to improve the batch uniformity. Bags with different melting points are suitable for different mixing conditions. Due to their low melting point and good compatibility with rubber, the bags together with the chemicals or additives inside can be direct put into a mixer. The bags can easily melt and fully disperse into the rubber as an effective ingredient. Using ZonpakTM batch inclusion bags can help rubber plants improve batch uniformity, provide cleaner work environment, save expensive additives, and raise efficiency.

Bags of different melting points, sizes, thickness, and colors are available to meet the customers’ requirement.

|

Technical Standards |

|

| Melting point | 65-110 deg. C |

| Physical properties | |

| Tensile strength | MD ≥16MPa TD ≥16MPa |

| Elongation at break | MD ≥400% TD ≥400% |

| Modulus at 100% elongation | MD ≥6MPa TD ≥3MPa |

| Appearance | |

| Surface of the product is flat and smooth, there is no wrinkle, no bubble. | |

Product detail pictures:

Related Product Guide:

We have advanced equipment. Our products are exported to the USA, the UK and so on, enjoying a good reputation among customers for 100% Original EVA Side Gusset Bags - Batch Inclusion Bags – Zonpak, The product will supply to all over the world, such as: Lebanon , Uganda , Yemen , We adopt advanced production equipment and technology, and perfect testing equipment and methods to ensure our product quality. With our high-level talents, scientific management, excellent teams, and attentive service, our merchandise are favored by domestic and foreign customers. With your support, we'll build a better tomorrow!

Goods just received, we are very satisfied, a very good supplier, hope to make persistent efforts to do better.